Home » Keywords: » Geometric Dimensioning and Tolerancing (GD&T)

Items Tagged with 'Geometric Dimensioning and Tolerancing (GD&T)'

ARTICLES

Measurement

ASME Y14.45-2021 Standardizes Measurement Data Content for GD&T Specifications.

Measurement

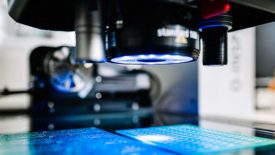

Metrology and Microscopy for Electronics Quality Assurance — in One Machine?

Compliance can often only be achieved through both metrology and microscopy tools.

March 5, 2024

Quality 101

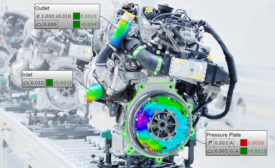

GD&T for Electric Vehicles Supports Consistent Quality Control

GD&T allows engineers to define feature relationships, ensuring proper alignment and interchangeability.

October 17, 2023

Aerospace | NDT in Aerospace

How Advancing CT Analysis Capabilities Support Collaboration and Product Quality

The looping of CT analysis via digital models can improve every aspect of the design-to-production cycle.

July 10, 2023

Quality Headline

NIMS Offers Innovative Teaching Technique to Make GDT a “Native Tongue”

June 13, 2022

What Is a Digital Twin?

Digital twin technology helps organizations to use real-time data, mockups, algorithms, and AI to create a virtual depiction of a physical object, process, or service.

May 9, 2022

Measurement

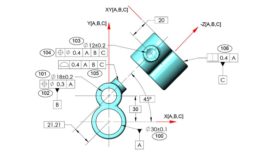

Geometric Dimensioning and Tolerancing

Let's review some of the elements of geometric dimensioning and tolerancing.

April 1, 2022

Sponsored Content

Why Knowing GD&T Inside Out is Essential in Machining Today

March 22, 2022

Sponsored Content

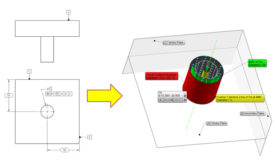

GD&T for Beginners: MMC & Bonus Tolerance, Explained in 3D

March 22, 2022

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing