Home » Keywords: » part inspection

Items Tagged with 'part inspection'

ARTICLES

It improves quality, increases speed to market, and reduces cost.

Read More

New Software Technology Advances the Practicality of Quality 4.0

It’s time to close the gap between Quality 4.0 and Industry 4.0.

October 8, 2019

Choosing Sensors for your CMM

The goal of part inspection is to get results you can trust.

July 1, 2019

Designing a Better Sensor for Small Parts Inspection

Smart technology advancements are at the heart of today's movement toward better sensor design.

March 1, 2019

Vision Sensors Set New Standard for Pass/Fail Inspections

By combining powerful vision tools, simple setup and a modular design, vision sensors set new standards for value, ease of use and flexibility.

April 30, 2018

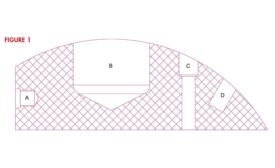

Depth Measurement Challenges

Let’s look at some of the part and gage features that may impede accurate depth measurement.

October 3, 2017

Vision & Sensors - Image Analysis

Encoder Input Improves Part Inspection

Adding an encoder to provide a distance-based input trigger can eliminate automated inspection errors.

May 8, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing