Home » Keywords: » lighting

Items Tagged with 'lighting'

ARTICLES

Vision & Sensors | Lighting

I hope to shed a little light on why blue is a superior LED choice over red now.

Read More

Vision & Sensors | Lighting

Liquid Lenses and Cameras: Unmatched Control over Optical Parameters

Learn more about liquid lens technology.

December 28, 2023

Vision & Sensors | Lighting

The Power of SWIR Illumination and Imaging

SWIR illumination and imaging unlock powerful new ways of differentiating materials that look similar under visible light.

December 11, 2023

New Product

Smart Vision Lights JWL150-DO Lightgistics Machine Vision Light

November 8, 2023

New Product

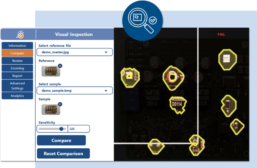

Pleora AI Inspection, Checklist Capabilities for Vaira Manufacturing Platform

October 3, 2023

Vision & Sensors | LIghting

Machine Vision Lighting Powers Industrial Automation Advances

Learn how lighting can optimize multispectral imaging, collaborative robots, and deep leaning applications.

July 3, 2023

Vision & Sensors | Optics

Core Concepts of Machine Vision Lighting

Proper lighting design is essential to assure a successful machine vision project. Ignoring this is one of the most common causes of machine vision project failures.

January 13, 2023

Vision & Sensors | Lighting

Creative Illumination Techniques Enable Computational Imaging

Computational imaging can simplify certain problems that are difficult to solve with standard visual imaging.

January 2, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing