Throughout the machine vision industry it has always been a challenge to keep 3D products in focus under the camera or to quickly scan various objects at different distances.

The vision system Depth of Field (i.e. the range of distances from the optics where the acquired image shows an “acceptable” focusing) is limited by several specifications, among the most important ones there is the diameter of the optics’ aperture stop (i.e. the working f-number). Since the Depth of Field increases proportionally to the f-number increase, vision systems which require long focusing ranges usually implements high f-number values. This choice must accept drastic limitations on the achievable image brightness and resolution, which limit the vision system acquisition speed and overall performances.

Traditional approaches to overcome those limitations use additional mechanics to change the distance between the camera and the focusing plane, or multiple cameras focused on different distances. Both these have strong limitations in terms of size, reliability and complexity, in particular when it comes to the vision system integration and software elaboration.

In particular, the prior has limitations in terms of size, speed and reliability. The latter results in a multiplication of equipment costs, furthermore the increased amount of images taken requires additional steps in the software development.

Liquid lens is a new technology which has been developed with the aim of making the adjustment of focus of the optic an easier process. This technology performs the change of focus using an electrical signal instead of a mechanical stimulation of the optic. In this article we will explore the working principles of liquid lenses, how to integrate them with industrial cameras and possible applications.

The liquid lens is a cell containing a liquid, this is sealed off with an elastic polymer membrane, all around there is a voice coil. The current is driven through the coil to produce a magnetic field, this causes the membrane to change its shape. By changing the shape, the performance of the whole optical system will change, in particular, the parameter that is affected the most by this is the working distance. Changing the shape of the liquid lens lets you focus on different planes within a certain range which depends on the design of the optic. This means that we are effectively able to refocus the optic at a different working distance by means of an electrical signal.

The liquid lens technology allows for a faster refocus compared to mechanical focusing by step motors or hand adjustment. Furthermore, the focus is more precise compared to the rotation of a focusing gear. This is a strong advantage of this technology because it increases the repeatability across different systems and different focus positions.

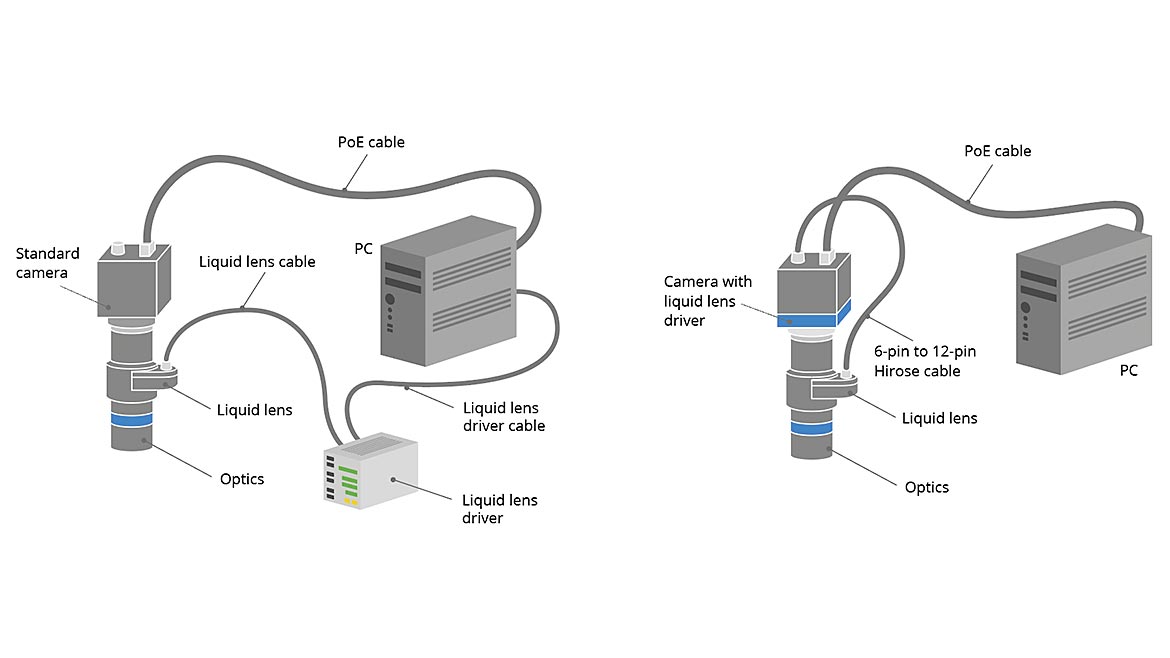

For what concerns the dimensions, the liquid lens is small, and it just adds a small Hirose 6 pin connector on the side of the optics. The design is compact and robust, and high reliability is assured thanks to billion cycles of tests. In addition, due to the absence of moving parts, it has a lower chance of breaking.

Integration with the camera

To control the liquid lens and supply the current we need a driver. Usually the driver could be either a USB stick or a circuit board, but these solutions require the integration of an additional product. A possible solution to this problem is to integrate the drivers of the liquid lens directly into the camera. Since each vision system has at least one camera, by having the lens driver directly in it, we are not required to use an additional component into the system.

The integration with the camera introduces several benefits:

- First, it simplifies the hardware, you have one less driver and one less cable. We can use, instead, a y-shaped cable to connect the lens to the hirose connector of the camera. Thanks to the y shape you also still have access to the flying leads of the cable, so you can manage triggering signals in input and output.

- Second, the integration of one less driver reduces costs. This is true not only from a money perspective, but also from a time perspective.

- Third, the integration is easier. Since the driver is integrated with the camera it will use the same communication protocol, on the other side using an external driver may require us to use an additional communication protocol.

The software part is also simplified, because with the camera with the integrated driver, only one software is required. Conversely, if using an external driver, the user needs two software, one for the camera and one for the lens when doing the development of the system. This may create issues since these two software have to be used in parallel and synchronized.

Figure 1 shows an example of a system with optics integrating liquid lens technology and a traditional camera (left) and with a camera equipped with liquid lens driver (right). You can see that using a traditional camera the system has an increased complexity due to the usage of an additional cable and driver.

The liquid lens can be driven in two different modes: current mode and power mode. By changing the current driven to the lens you are changing its focal power and vice versa, but you need to pay attention because the focal power is a function of both the current and the temperature of the lens.

Focal Power [dpt] = f(Temperature [C°],Current [A])

- Current Mode: This mode allows the liquid lens to maintain a constant current, but the optical power begins to shift as the temperature of the lens changes.

- Power Mode: This mode allows the optical power to be fixed at a predefined value. When the temperature changes, the current also changes, in order to maintain a constant optical power.

This second mode is incredibly useful because by fixing the optical power, the focus remains stable, and it is not lost during the acquisition. The implementation of this mode is possible because of the presence of a temperature sensor on the liquid lens. These functions have been implemented on the internal driver of the camera, so they are easily accessible from the GenICam tree. Using GenICam or GigE Vision communication interfaces it is possible to set up these two modes and use the liquid lens.

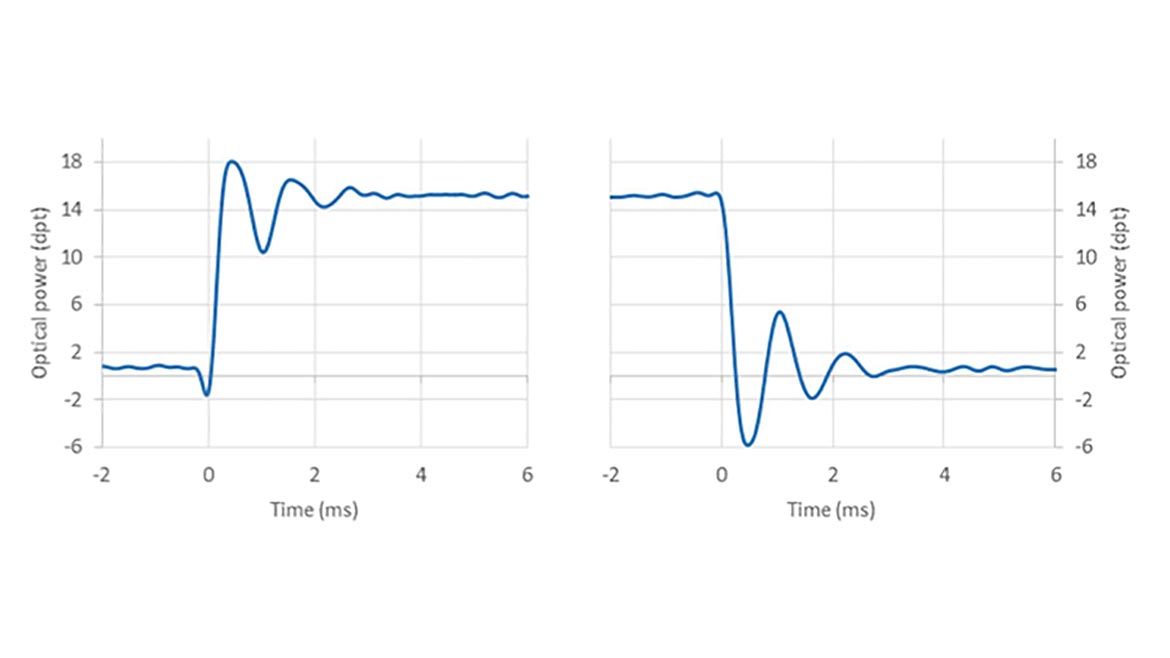

When the focus is changed, the response time and the setting time must be also taken into account. The response time is the time which the liquid lens takes to change its focal power in response to the given current change. The setting time is the time required for the full stabilization of the optical power.

Figure 2 reports an example of what is mentioned. In this case the response time is equal to 1 [ms], while the setting time is equal to 4 [ms]. This means that to have a totally stabilized focus, the user has to wait 5 [ms].

Application Examples

There are several applications where the liquid lens could be used with great results.

One example is the pharma industries. In this field, for traceability purposes, a complete inspection of vial caps is always required. In particular is it asked to the vision system to be able to perform OCR or matrix data reading. When dealing with large or different sample sizes, multi-camera systems are the preferred solution, but they are complex and cumbersome. The use of liquid lens would eliminate the problem since the system can automatically refocus when changing the format of the product.

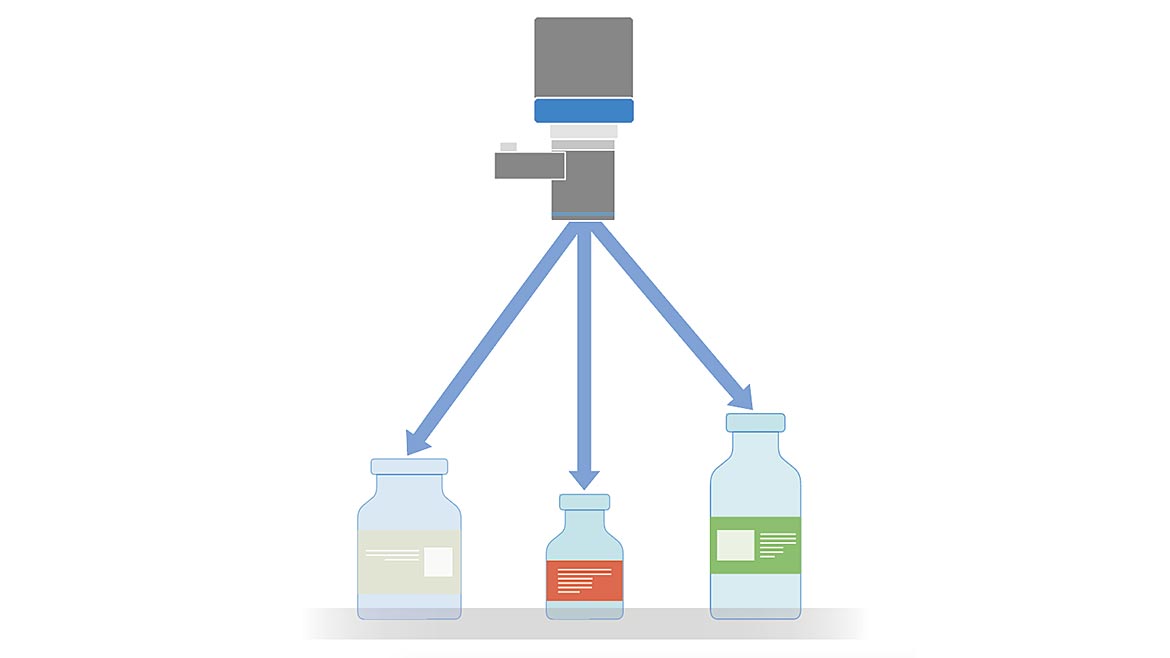

Another field is the beverage sector, where bottles and cans have different formats and are at a different working distance. Figure 3 better explains this concept.

For example, consider a conveyor, where the bottles slide at a constant speed. The samples need to be recognized and we want the system to read a barcode that is printed on the cap. In this case the focus must be adapted every time because the dimensions of the cap change and the working distance changes too. Without using a liquid lens a mechanical arm has to be programmed to turn the focus gear. In addition to the encumbrances, this also adds vibrations to the system and could cause unwanted displacement of the camera or of the bottles. This type of application strongly recommends the use of a liquid lens due to its ability to provide rapid responses and the flexibility to adjust focus through software, in addition to other advantages.

Vision & Sensors

A Quality Special Section

In conclusion, it can be asserted that liquid lens technology has the capacity to streamline vision systems that face the task of working with format changes. The main advantages are the increase of versatility of the system and the repeatability that you can achieve compared to a mechanical system.

Furthermore, the seamless integration with cameras confers an additional benefit, facilitating the accessibility of this technology. This development increases the potential for new applications in the foreseeable future thanks to the additional versatility provided by this technology.