Home » Keywords: » 3D imaging

Items Tagged with '3D imaging'

ARTICLES

Quality Headline

Digital 3D Touch Sensor Wins Hexagon’s Support to Scale, Solve Industry Challenges

February 7, 2023

Vision & Sensors | Trends

Trends in the Machine Vision Market

Observations on the market and the technologies that could be the next to impact applications in automation.

January 4, 2023

Vision & Sensors | Machine Vision 101

Machine Vision Standards: A Review and Update

Over machine vision's long history in industrial automation, the emergence and development of standards has been one of the key drivers in advancing this technology.

January 3, 2023

Vision & Sensors | Lighting

Creative Illumination Techniques Enable Computational Imaging

Computational imaging can simplify certain problems that are difficult to solve with standard visual imaging.

January 2, 2023

Vision & Sensors | Trends

Machine Vision Developments Drive Automation Upward

As business needs grow and transform over time, suppliers continue pushing machine vision technology forward.

December 9, 2022

Sponsored Content

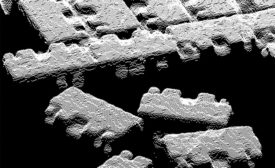

White Paper: University Uses Advanced Micro-CT Scanning for Inspection of Historical Artifacts

October 28, 2021

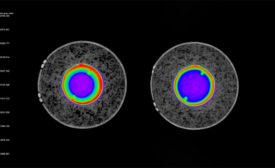

Computed Tomography: Back to Basics

Computed tomography is a powerful nondestructive evaluation (NDE) technique for both 2D and 3D cross-sectional images of an object from X-ray images.

July 1, 2020

Quality in Automation > Robotics

The Need for 3D Imaging Performance Standards for Robotic Assembly

NIST is working with the 3D imaging industry to develop performance standards for systems that can be used for robotic assembly applications.

April 6, 2020

Machine Vision Trends

A look at the most talked-about machine vision technologies, their practical uses and limitations, and which will have a long-lasting impact on your current and fixture applications.

September 1, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing