Home » Keywords: » x-ray fluorescence

Items Tagged with 'x-ray fluorescence'

ARTICLES

NDT | XRF

It is crucial that the compositions of metals and alloys used in automotive fasteners are verified through stringent quality assurance.

Read More

NDT | XRF

How to Measure Metal Coating Thickness Using Handheld X-ray Fluorescence Analyzers

Handheld XRF is an indispensable tool in quality assurance that provides multiple benefits.

February 8, 2022

Back 2 Basics

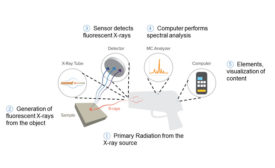

The 101 on XRF Analyzers

Experts share details on the ins and outs of this technology

April 8, 2021

Handheld XRF, OES, and Portable LIBS Analyzers— Which One Is Best for Your Needs?

Understanding the limitations and differences in each of these techniques is critical when performing material analysis.

June 24, 2020

X-Ray Fluorescence (XRF) Frequently Asked Questions

You can point an XRF analyzer at almost anything and get a result.

April 8, 2020

Back to Basics: Detecting Heavy Metals Using X-Ray Fluorescence

Beginner tips to understand the role XRF plays in restricting hazardous materials.

October 2, 2018

With XRF Measurement, the Goal is Achieving Low Limits of Detection Precisely—and Fast

Here’s how to get there.

June 8, 2018

XRF 101: Choosing the Right Analyzer

Consider these seven points to help you identify what tool best meets your needs.

November 13, 2017

Triboluminescence: Enabling Major Advances in XRF

Triboluminescent X-ray generation has had a profound impact on XRF technologies.

October 17, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1621530074&width=275)