Home » Keywords: » radiography

Items Tagged with 'radiography'

ARTICLES

Column | Marty Wenzig

The Achievements of Radiographic NDT

Read More

NDT | Radiography

2D Radiography (x-ray) for NDT

2D radiography continues to be essential to the safety and reliability of many of the world's industrial products.

October 11, 2022

NDT Trends

Nondestructive Testing (NDT) Trends

Manual means of performing NDT and human evaluation of the results is trending more and more to automated, digitized and artificial intelligence interpretation of the results whenever economically possible.

October 10, 2022

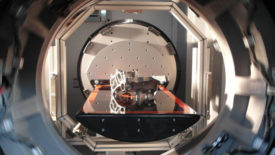

NDT | Computed Tomography

How Nondestructive Testing is Driving Sustainable Quality in the Automotive Sector

NDT techniques are available that are just as quick as destructive methods but also offer a more sustainable use of raw materials.

February 8, 2022

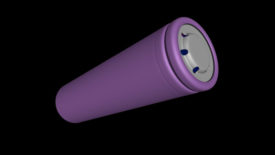

NDT | Computed Tomography

Computed Tomography's Solution to Battery Safety Concerns

A battery is a great example of the value of CT compared to simple radiography.

February 8, 2022

NDT | Radiography

Neutron Radiography and Turbine Blades

Neutron Radiography Works on the Same Basic Principles as X-Ray Imaging Except With Neutron Radiation Instead of X-Radiation.

June 8, 2021

NDT | Back 2 Basics

The Basics of Digital X-Ray Inspection

Conventional Radiography Will Continue to Have a Pace in NDT, but Digital Radiography is the Future

June 7, 2021

How Neutron Radiography Works

Modern technology is closing the technology and accessibility gap between N-ray and X-ray imaging.

November 30, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing