What geometric dimensioning and tolerancing (GD&T) is depends on one’s discipline. To the designer it is a way to describe the design intent of individual parts. To someone in production it is the language of modern print reading. To someone working in metrology it is a guide to the inspection of parts. To management it is a concurrent engineering tool that provides clear communication across the enterprise.

GD&T has been developing during the past 80 to 100 years. It really started to be applied during World War II when the military realized the importance of defining parts with a document that had only one meaning to ensure interchangeability and part functionality. For many years companies, countries and the military published their own version of GD&T. This caused much confusion for suppliers trying to produce parts for multiple customers.

Today most companies, from those that produce aircraft carriers to those that produce cell phones, satellites or sump pumps, have committed to following either the ASME Y14.5M-1994 standard or the collection of ISO standards on GD&T. The ASME Y14.5 standard has emerged as the preferred standard in the United States and several foreign countries, mainly because of its stability, emphasis on design intent, mathematical definition and translation to several languages.

In addition, there is now the ASME Y14.41-2003 standard, which sets forth the rules to applying the Y14.5 dimensioning and tolerancing concepts to digital data such as solid models. Dimensions and tolerances can now be embedded in the CAD model. Embedding tolerances in the solid (digital) model opens the door to reduced dimension drawings and automated analysis, which can include the expected variation which is bound to occur in production. GD&T enables this change in technology. According to ASME Y14.100 the word drawing now refers to the paper document or digital data.

Directly Toleranced Dimensions

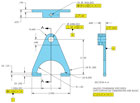

Dimensions may be directly or indirectly toleranced. Directly toleranced dimensions are those that are not basic. Directly toleranced dimensions may have a tolerance written next to the dimension, be limit dimensions or make use of a general title block tolerance. The drawing in Figure 1 illustrates common tolerancing methods. In addition to the tolerancing shown, tolerances may be unequal bilateral, or applied by using limits and fits tolerance symbols, or by referencing implied tolerances found in standards such as ISO 2768.Limit dimensioning: 14.1 14.0

Plus and minus tolerancing:

- Unilateral: 30 +0.1/0

Equal Bilateral: Ø12±0.1

Title block tolerance:

- Linear tolerance: ±0.2

Applies to Ø100, Ø50, 30, 10 and two R3s

Angular tolerance: ±2°

Applies to the implied 90° angles

Basic Dimensions

Basic dimensions do not have a direct tolerance. The basic dimensions in Figure 1 are Ø76 and 40. By making these dimensions basic, the general tolerances no longer apply. Their tolerance is indirect. The tolerance is applied to the features on the part, not the dimensions. The basic dimension may be thought of as the goal and the geometric tolerance is the amount the feature may deviate from the goal.Geometric Tolerances

Where geometric tolerances are used, they are applied to the feature rather than the dimension. The geometric tolerances are found in the feature control frames. In Figure 1 they are Ø0, 0, 0.1, 0.2 and three Ø0.3.Even though there are 0s in some of the feature control frames, it does not mean that production must make perfect parts. The 0 tolerance applies only at one limit of size known as the maximum material condition (MMC) or the least material condition (LMC). Using 0 tolerancing actually provides production with more tolerance because it allows the acceptance of the best parts. This was not possible without GD&T.

Size Dimensions

The size dimensions in Figure 1 are Ø30, Ø100, Ø50, Ø12 and 14.1/14.0. The 10 and 30 dimensions use the dimension origin symbol in place of an arrowhead to indicate which surface functions as a “local datum feature” for inspection.

- Multiple interpretations.

- Tolerancing of points in space that cannot be verified, such as the center of a radius.

- Tolerance accumulation.

- Wedge-shaped tolerance zones where angles are toleranced in degrees.

There are four categories of geometric tolerance characteristics: location, orientation, size (handled with direct tolerancing not shown in chart) and form. There is a hierarchy to these geometric characteristics. Location tolerances also control the orientation of features. Size also controls form.