The current trends in manufacturing can be summed up pretty much as they always have been: more for less. In other words, manufacturers always want to be able to do more with less. With manufacturing evolving into a globally competitive marketplace over the last few decades, precision, accuracy, and speed have become essential in order for manufacturers to remain competitive. Optical metrology is quickly becoming the go-to technology in order to achieve competitiveness by delivering more for less.

What is optical metrology?

Once seen as the pariah of measurement systems, optical systems were widely distrusted due to very poorly understood concepts of light refraction, light wavelengths, and more. Even today optical systems are still looked at in some ways as unreliable, even though optical metrology itself is a simple concept and various forms of it have been around for decades (optical comparators are a good example). It wasn’t until recent advancements in optics, computers, and even information processing techniques that companies have finally begun to harness the true power of optical metrology. Fast and powerful computers, high resolution sensors, powerful computer programs, data processing capabilities and more have all led to advancements in using various forms of optical metrology in manufacturing industries such as automotive, medical, semiconductor, aerospace and defense.

Tech Tips

Contact, noncontact, pneumatic, optical, microscopes, and more, are all vying to remain, or become, the primary method of part evaluation for a vast array of part manufacturers around the world.

There have been advancements at every level of metrology, yet even with all the advancements in technology, optical metrology systems remain the fastest, most flexible method of evaluating part quality.

If you’re looking to do more with less, optical systems may be the best way to evaluate your part quality

Industries

Nowhere is the advancement of optical metrology more critical than it is in the automotive market. With over a dozen major automotive manufacturers and hundreds of smaller ones, adoption of optical metrology technology will grow rapidly over the next decade. Work piece inspection such as distance, surface finish, flaw detection, contour, and diameter are all viable tolerances for optical systems to measure. As the industry continues to make improvements in the basic technology and expands its knowledge in utilizing new techniques, researching new hardware, and looking to expand beyond today’s accepted boundaries, optical metrology will be there to meet the demand. Let’s explore some of these to see where the industry is and where it might be headed in the future.

Surface Finish

Surface finish is a critical feature on an ever increasing number of manufactured automotive parts. Connecting rods, engine blocks, cylinder heads, cam shafts, crank shafts, and body panels are all being increasingly scrutinized when it comes to their surface finish characteristics.

You might be asking yourself why manufacturers are looking at surface finish, until you understand that surface finish characteristics plays a big role in oil retention, engine temperature, part weight, product sealing properties, noise vibration harshness (NVH), rolling resistance, and even paint adhesion to vehicle surfaces. Up until just a few years ago, most (if not all) of these would have been checked using contact systems of one type or another, including CMMs, bench top surface finish checkers, and even handheld units manufactured from a variety of metrology companies.

Recent advancements in understanding light, mathematics and more have allowed manufacturers to start implementing some of these checks using specific types of optical metrology. Optical solutions to measure some of these characteristics consist of white light sensors for painted vehicle surfaces, specialized microscope sensors for determining the roughness of polished surfaces, and even lasers to determine XXX under carefully controlled measuring applications.

Determining actual roughness on manufactured parts using optical metrology is considered by many to be the Holy Grail for both manufacturers and metrology manufacturers. Nevertheless, as advancements continue to be made in sensor technology and measurement techniques the manufacturing industry will see an increasingly larger share of manufacturers using optical metrology to determine critical surface finish characteristics.

Flaw Detection

Flaw detection used to be done manually (ever heard the saying “just eyeball it?”), and still is in some industries, but the newer optical systems excel at detecting flaws on a variety of different surfaces, like cylinder heads, connecting rods, valve bodies, interior and exterior surfaces on engine blocks, and much, much more.

Most individuals think of the semi-conductor industry when it comes to flaw detection, but the automotive industry has invested in flaw detection systems for a variety of reasons, several of which are to verify that the surface will seal as intended, lubricates properly while the vehicle is running, or that the surface has been prepared correctly in order to be finished with a specialized coating or process. Typically these types of systems are fully automatic, with robots or automation controlling the optical sensors (to eliminate operator influence), and parts being introduced on the fly via conveyors, or other part handling processes. Optical flaw detection will continue to grow in the automotive market, especially when controlling surfaces for lubrication and sealing properties.

Dimensional Measurement

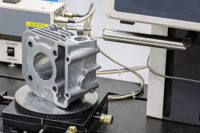

Dimensional tolerances are some of the easiest measurements to collect with optical gaging, making its widespread adoption in many industries fairly rapid over the last fifteen years. An early trend was to use optical gaging for determining length, diameter, radius, angles, etc., on machined parts like crankshafts, camshafts, turned and precision turned parts, and turbo chargers.

With new advances in sensors, a recent addition to the fold of dimensional gaging can be used to measure dove-tail profiles in cylinders. This type of check is used to determine if the surface was activated correctly (i.e. roughened properly) in order to precisely apply thermal spraying of the cylinder bores in an engine block. For those unfamiliar with the process, thermal spray technology is one way that automotive manufacturers are reducing vehicle weight by thermally coating bores with steel instead of using press fit cylinder liners, which is then honed to a specific size. With the trend accelerating, most engine manufacturers will be using thermal spray techniques within just a few years and each and every one of them will most likely require optical metrology systems to verify manufacturing requirements are met.

Form and Position

There has been widespread adoption of various systems capable of measuring form and position features on manufactured parts, especially pertaining to turned and precision turned parts, camshafts, crankshafts, bearings, and electric motor components.

Since these types of features were one of the earliest to be checked using optical systems, thousands of these systems have been installed worldwide at major car companies, military suppliers, and medical facilities. One of the benefits of early adoption is that these systems are fully mature technology-wise and deliver the full benefits of optical metrology: fast and powerful computers, robust mechanical construction, high resolution (HR) camera systems, and high speed data acquisition. In addition, the mathematics behind these systems have been proven and meet international metrology standards around the world.

Conclusion

It’s an exciting time to participate in today’s manufacturing world. At no point in history have there been as many different ways of quantifying part quality as there are in many of today’s industries.

Contact, noncontact, pneumatic, optical, and microscopes are all vying to remain, or become, the primary method of part evaluation for a vast array of part manufacturers around the world. There have been advancements at every level of metrology, refreshing older technologies (like pneumatic measurement), creating new ones (white light and laser), yet even with all the advancements in technology, optical metrology systems remain the fastest, most flexible method of evaluating part quality.

No other measuring method is capable of evaluating so many data points as quickly and as precisely as optical systems can, so if you’re looking to do more with less, optical systems may be the best way to evaluate your part quality.