Virtually every manufacturer must perform some kind of testing or inspection to ensure their products meet their own internal quality standards, governmental requirements or the standards their customers set. A growing number of industries use some form of nondestructive testing (NDT) to ensure that structural and mechanical components perform their function in a safe, reliable, and cost-effective manner. Given that NDT doesn’t alter the article being inspected, it can save both money and time in product evaluation, troubleshooting, and research. Although there are a wide variety of NDT methods, some of the most common ones include ultrasonic testing, visual and optical testing, magnetic particle testing, penetrant testing, eddy current testing, and low coherence interferometry. Digital radiography, including computed tomography and metrology, has become a particularly popular choice because of the advantages it offers over traditional X-rays, including greater time efficiency through eliminating chemical processing, the ability to transfer and enhance images digitally, and the lower level of radiation required. Once the most appropriate form of NDT is determined for a particular application, a manufacturer must decide whether to perform these inspections in-house with an existing system or to purchase a new system, which can represent a major investment for any company. The other option is to farm them out to a third-party inspection service.

Buying inspection equipment vs. buying inspection services

In order for a manufacturing operation to make that buy-equipment vs. buy-services decision intelligently, management needs to answer a number of important questions. For the purposes of illustration, we will use digital radiography equipment as an example to examine these questions.

How often do you need digital scanning services in order to run your business?

If the demand is intermittent and fairly time-insensitive (i.e., if you don’t need inspections performed immediately to keep a production line operating), buying inspection services probably makes sense for you. Let’s say that you just need to scan some prototypes to ensure they meet your internal specifications before transitioning into full production. Or if a particular application is only seasonal (such as a product that is only manufactured for a limited period), you should also consider buying inspection services rather than investing in a system that will sit idle for most of the year. However, it’s important to take all the time necessary to do a careful review of all the radiography applications involved (or parts that could be inspected radiographically) and how frequently they are called for.

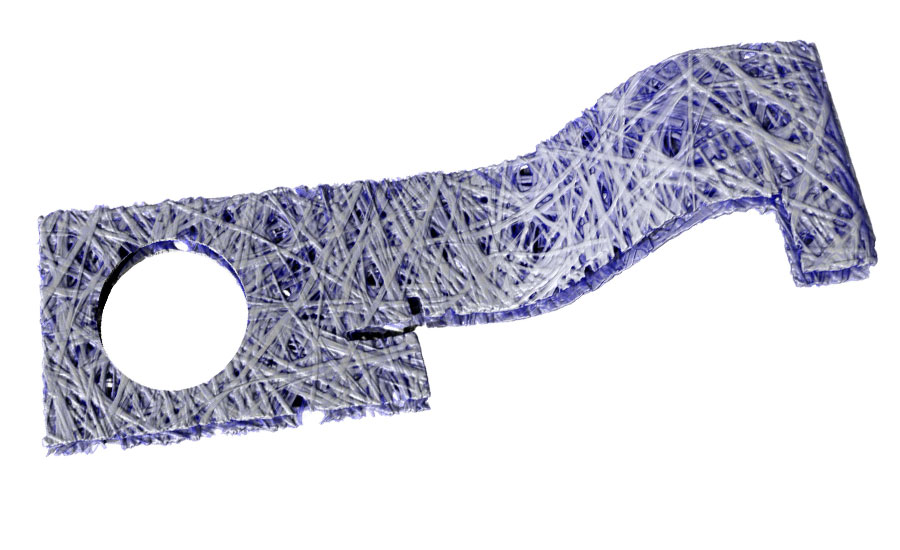

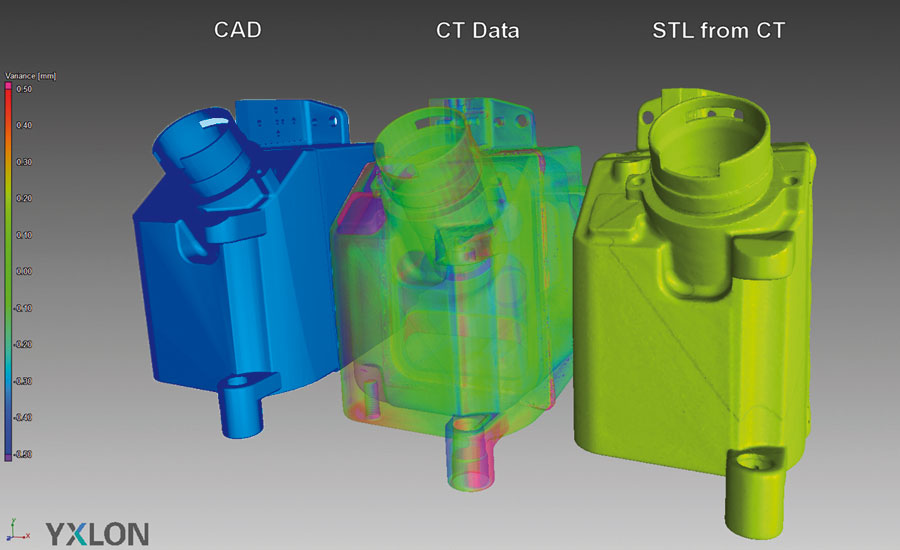

CT Scan of Carbon Fiber Part. Source: XYLON

Do the inspection services you’re considering offer the specific capabilities you need?

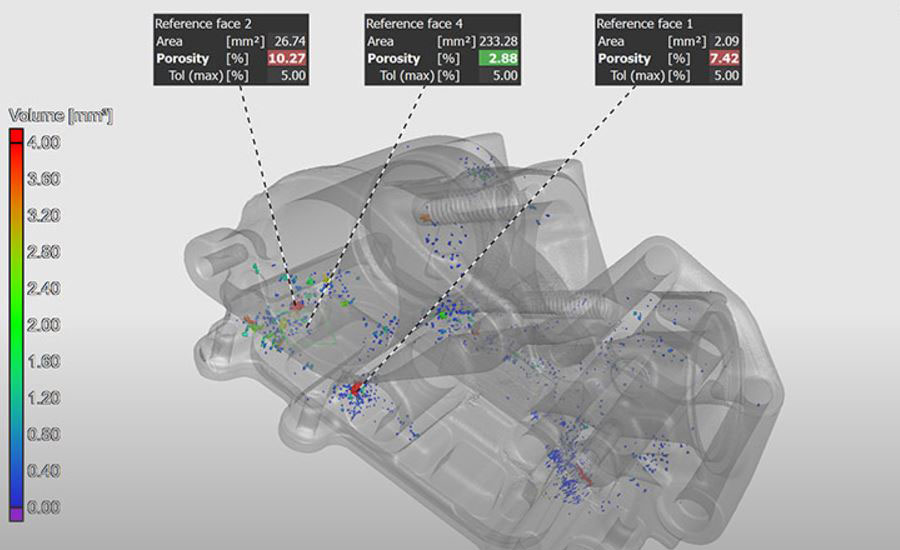

Not all inspection services can supply the same types and quality of inspections as others. For example, check to make sure the inspection provider has the equipment and qualified personnel necessary to perform the specific services you need, like defect and porosity identification, internal inspection and validation, dimensional measurement capture for metrology or reverse engineering for 3D printing, etc.

CT Image of Porosity. Source: XYLON

How much experience does the inspection service have in scanning the kinds of objects you need scanned?

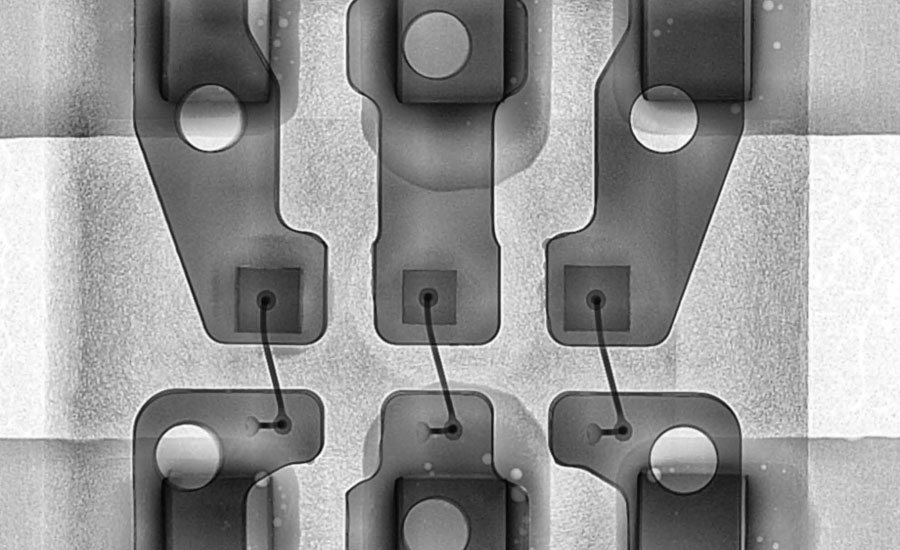

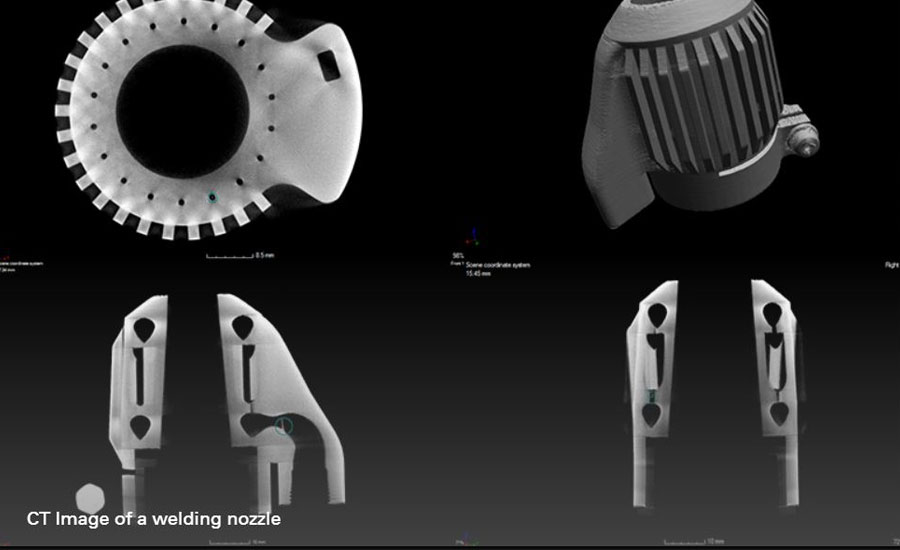

Computed tomography is often applied to scanning objects as diverse as electronics, cast metal parts, cultural/archaeological artifacts, aerospace components, vertebrate anatomy, rock/drilling samples, implants, etc. It’s also often applied in research, such as in new materials development. However, getting the clearest, highest resolution image when scanning these objects requires familiarity with both the type of object and the types of equipment and software best suited to scanning it.

Are you planning to add new services/products that will demand greater/faster access to digital scanning services?

Changing customer demands are inevitable, so start talking to customers early about their future needs. If their customers are demanding greater verification of part quality, having an in-house system may offer the flexibility you need to supply it. A thorough cost/benefit assessment is essential to justify a system purchase of this type.

Are your customers demanding faster turnaround/delivery on parts?

If you discover a major customer is planning on tightening their turnaround time requirements to implement just-in-time manufacturing, purchasing an in-house system might make an important difference in the lead times you can quote. Or if the need is sporadic, third-party inspection service providers can serve as an extension of your production line and help keep you on schedule.

Do you plan to introduce any products that will require high-resolution scanning to ensure you are meeting your own in-house specs?

Research and development activities often require the ability to scan objects to gauge the impact of minor changes to a form or design. Having an in-house inspection system with the capability to do dimensional and quantitative measurements on the interior of your product would speed up the trial and review process substantially, reducing time to market. However, if your R&D needs are few and far between, the third-party inspection service provider will likely be a better fit.

Are your end-users requiring you to meet a new set of production standards?

New standards can be the result of a variety of factors, such as new governmental requirements, an updated industry standard, a sudden rash of recalled parts, etc. For example, several international aerospace material standards were created by ASTM (American Society for Testing and Materials) for digital radiography. They have been readily adopted and are referred to frequently (such as ASTM E2736, E2699, E2597, E2698 and E2737). Together, they address topics ranging from the long-term stability of digital detector arrays to guidelines on the best way to implement this technology. The benefit of third-party inspection services is that they have these certifications and past experience in testing to these standards.

CT image of a Welding Nozzle. Source: XYLON

Are you planning to transition from your current film radiography equipment to digital?

If so, be aware that this transition will require significant planning, time, money and effort. Inspection services might offer a good way to bridge the gap while you are investigating the type of equipment you want to purchase, getting it installed, training personnel, etc. For more information on making this transition, download a free guide, Managing a Successful Transition from Film to Digital Radiography.

Are you weighing various scanning options for a future purchase?

Although it may sound counter-intuitive, using an inspection service with a range of equipment offers a good way to evaluate the quality of the output of a particular system before you buy. In this way, you can eliminate surprises after you buy a system and you can be more confident that the results obtained through the inspection service will correlate well with those obtained from your in-house system.

How large are the parts that you want to scan?

If your operation will regularly require the ability to scan larger parts, buying an in-house system optimized for larger objects is likely the most economical solution. However, if there will be only a few oversized/unusual scan requirements, it might be best to buy one system that’s sized for the work that must be done regularly but “farm out” the ones that are only rarely needed.

Is there a competitively priced inspection service provider who can perform the services you need with the quality your process demands and in a workable timeframe?

If not, you’ll likely need to invest in an in-house system to keep your own operation on schedule. The following sub-points can help you explore your options.

- Compare prices from multiple inspection services that offer the specific set of capabilities you require. Don’t hesitate to request quotes from multiple service providers on the same project to ensure an apples-to-apples comparison.

- Do a trial project to evaluate the quality of the image that each service provider’s equipment is capable of producing. Again, have scans of the same piece performed by multiple providers in order to make an apples-to-apples comparison.

- Investigate the level of training of the personnel who will perform the scan. Although third-party service providers all generally work within international standards, such as ISO (International Organization for Standardization) and previously mentioned ASTM, all scans are not created equal. Image quality often depends almost as much on the skill of the operator as it does on the sophistication of the equipment used. Most systems, regardless of manufacturer, are working with much the same third-party software to produce results. That means the true differentiators between one service provider and another is the quality of the system used and the skill of the operator. Although competitive price is important, it’s of small comfort when the final result is an image that doesn’t capture the part features you need to visualize.

- What are the quoted turnaround times for the various services? Don’t forget to factor shipping times into this turnaround time. Look for a service provider with multiple locations that is capable of performing the specific scans you need quickly. For consistent quality worldwide, find a trusted player in the global marketplace.

- How up to date is the equipment that will be used to perform the scans? In general, the newest systems provide the highest resolution/best image available. A vendor service provider should update their equipment and software on a regular basis, to assure the highest quality results and the most reliable service.

Conclusion

Just as no single digital radiography system is right for every application, no single inspection service is right for every nondestructive X-ray testing need. However, with careful research and the willingness to ask some probing questions, you can make smart decisions about whether in-house equipment or third-party services make the most sense for your organization.