Home » Keywords: » inspection methods

Items Tagged with 'inspection methods'

ARTICLES

TEST & INSPECTION

As Manufacturers Embrace Increasingly Complex Materials and Processes, Their Inspection Methods Evolve with Them.

Read More

Quality in Automation > Inspection

How to Automate your Inspection Process

New sensors, mobile systems and thorough communication can help manufacturers overcome previous hurdles.

April 4, 2020

Additive Quality

The greatest challenge of AM is the verification of parts’ absolute reliability.

April 1, 2020

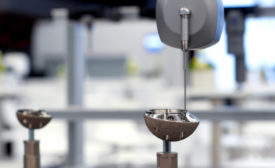

Metrology for the Medical Field

Medical devices require stringent quality and inspection methods.

March 1, 2020

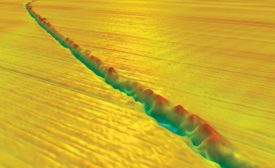

Choosing and Applying NDT Methods for Round Stock during Production

There are many approaches to NDT inspection, ranging from full system tests to in-process inspection of partially finished products.

November 8, 2019

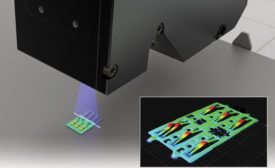

Designing a Better Sensor for Small Parts Inspection

Smart technology advancements are at the heart of today's movement toward better sensor design.

March 1, 2019

Third-Party Industrial Computed Tomography (CT) and Digital X-ray Inspection Services

Are they right for your business?

April 2, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing