Home » Keywords: » CT technology

Items Tagged with 'CT technology'

ARTICLES

NDT | Back 2 Basics

Besides the automation of a CT system for NDE 4.0, it is very important to digitize the whole process for NDE.

Read More

Computed Tomography’s Role

Accelerating time to market and improving profitability

March 3, 2021

Additive Drives the Adoption of CT for Nondestructive Internal Inspection

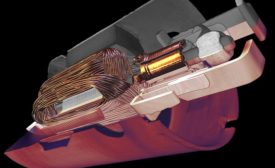

CT provides unparalleled insight into a 3D structure, including its density at every point throughout its volume.

November 30, 2020

Understanding Accuracy for Computed Tomography

If you take time to understand these definitions, standards and testing methods, you’ll be able to determine the accuracy of CT in your specific application.

October 5, 2020

Sponsored Content

The Future is Now: The Impact of Industrial Computerized Tomography on the Castings Industry

October 18, 2019

Computed Tomography: A Look Inside

CT is paving the way and creating opportunities.

August 8, 2019

Third-Party Industrial Computed Tomography (CT) and Digital X-ray Inspection Services

Are they right for your business?

April 2, 2018

Computed Tomography Analysis Techniques

Industrial computed tomography cuts deep for applications beyond just porosity analysis.

April 2, 2018

Radiography Trends Lead to High Speed CT

Today’s digital radiography is far beyond what early radiographers could have imagined.

April 2, 2018

Redefining Aerospace Inspection with CT

While many NDT methods are available, industrial computed tomography is redefining the limits of inspection.

October 17, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing