Modern digital gaging streamlines the measurement process, makes measurement faster and hastens data collection.

But an additional benefit that organizations might not be aware of, and which is simply a byproduct of the capability afforded by digital technology, is accessibility—accessibility both in terms of aiding those with sight or movement issues, and in terms of helping newer or inexperienced workers do their job in an easier and more effective manner.

Taking Advantage Of Modern Digital Capabilities

When digital measurement tools first came on the scene, features that helped make operation easier for a user included things like small LCD displays, or digital outputs that could be plugged into a device that enabled measurements to be read aloud.

Today, those features still exist, but there are additional capabilities of modern digital gages that allow for even greater ease of use and accessibility for all users. And while these capabilities were not designed or intended to increase accessibility, the benefits have become a natural offshoot of modern tech advances.

Whether helping new hires operate at a higher level faster or helping someone with poor eyesight get a better read on measurement results, shops should be aware of these underused capabilities that have been available for years.

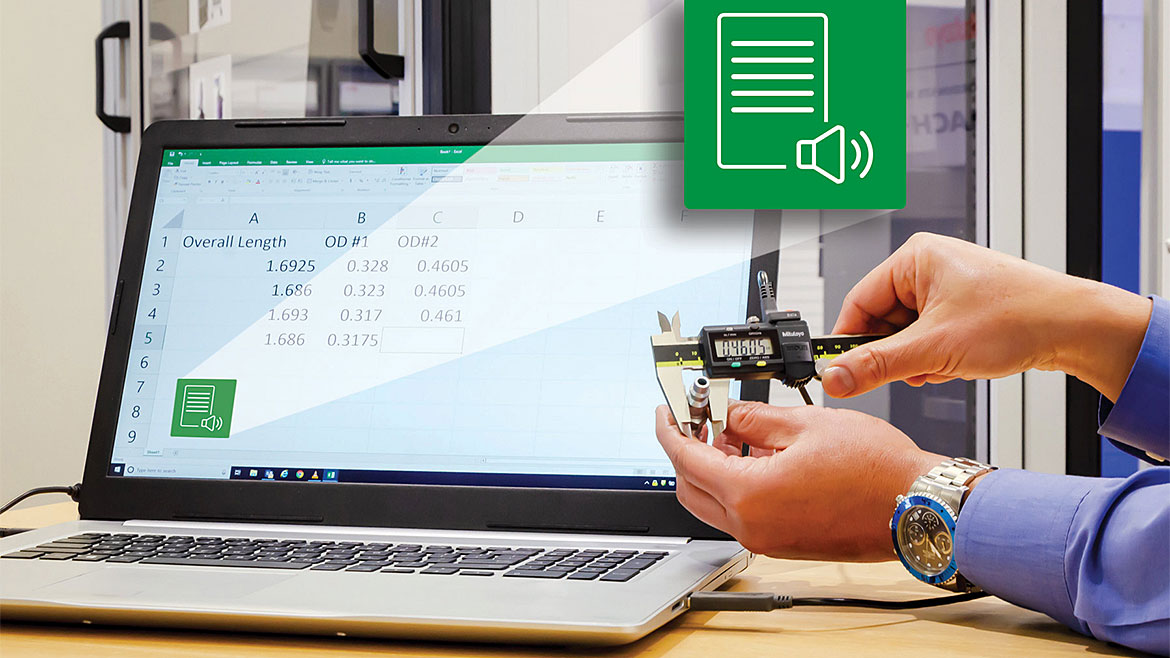

Many software packages have options that read aloud each measurement. Data can be sent directly to the PC with a footswitch or push of a button. Image Source: Mitutoyo

Features Within Excel That Integrate With Windows And Allow For Streamlined Workflows And Easier Data Reading:

- Ability to hit a button and, wired or wirelessly, send data directly into the interface.

- A text-to-speech feature can be activated that, once data is input and you hit enter, will automatically read the information aloud.

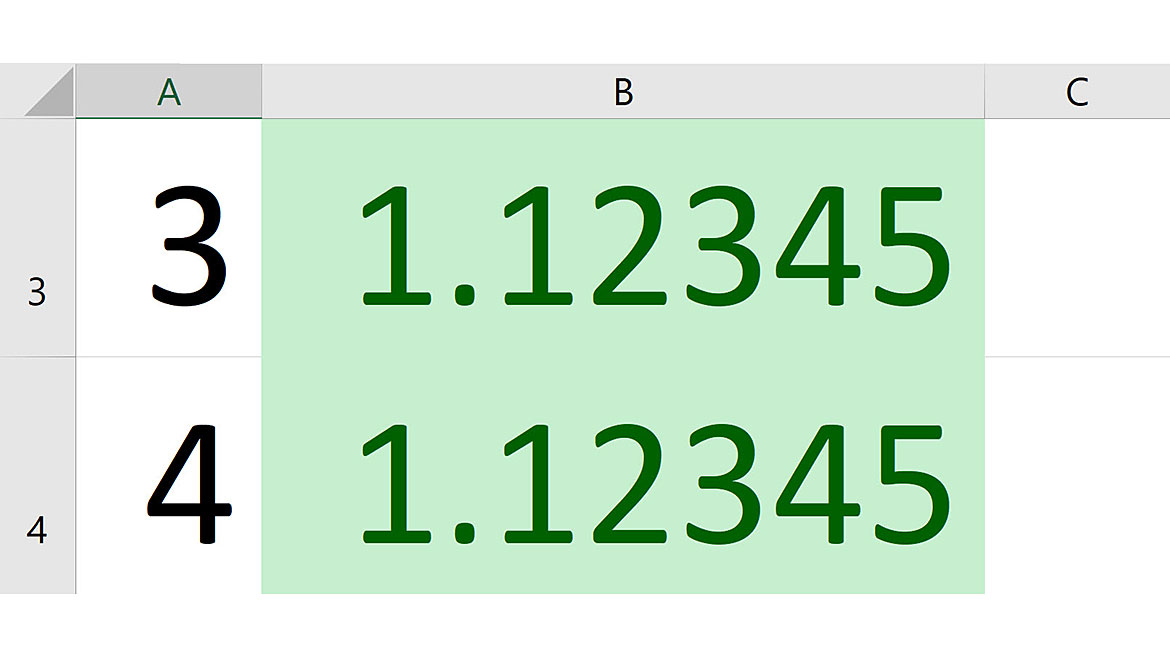

- Within Excel, the ability to enlarge the cells so that data is easier to read and see.

- Conditional formatting of an entire cell could allow for highlighting green or red, depending on the tolerances entered, to quickly visually determine if readings are out-of-tolerance.

Under-The-Radar Features That Provide Further Ease Of Use For Digital Gages:

- Wireless Bluetooth applications that can reside on a smartphone and allow the user to see a measurement on a tablet or laptop.

- Voice commands that work with software other than Excel, which can trigger data entry by the operator simply saying a phrase like “press space” to send a request from the software that triggers the measurement tool being used to send its reading.

- Operators can elect to use a foot switch to automatically send readouts instead of using a handheld push button. Whether an operator has limited mobility, is looking for an ergonomic alternative to reaching around to hit a button or has his or her hands busy doing other tasks, this allows one to send the data in a way that’s most convenient. This could also help keep fixtures from flexing due to the force being exerted by pressing a button.

- The use of a larger interface to visualize data versus reading a small LCD display on a caliper, micrometer, height gage or other measuring tool.

- Interfaces can interact with software to produce indicator bars or meter charts. For example, a meter chart can depict a needle going in one direction or another to indicate whether a reading is close to being out-of-spec. This eliminates the need to read an actual number and provides a faster, more intuitive way to evaluate the manufacturing process or accomplish a quality control check.

- Green or red backlit indicators can function as a fast, easy way to arrive at a go or no-go judgment. Given many operators receive less training today to make up for the worker shortage, this helps operators learn quickly while also supporting greater accuracy.

- Additionally, software can automatically send an email notification if measurement is out of spec, so QC managers are aware.

Excel spreadsheets can be zoomed in closer to make the reading of measurements possible and easier for operators with poor eyesight. Image Source: Mitutoyo

Looking Ahead

Today’s digital gages provide ways to automatically see and track measurement data, which both saves time and creates a more reliable data input that doesn’t require a person to physically record and transcribe information. It also provides a greater range of data output options.

This ease of accessibility is a byproduct of modern design, and a beneficial one at that. It allows for those with visual or mobility issues to more easily address measuring tasks, enables organizations facing machinist and operator shortages to maintain productivity and better support inexperienced or newly trained workers, and makes for more convenient operation for anyone using digital gages and other digital measuring tools.

However, even with these beneficial digital gaging features, manual gaging is still popular in the industry, given these are tools many machinists are comfortable with, and which they know they can depend on.

Without a doubt, manual measuring devices have a place in modern measurement. And machinists and shops that are reticent of straying from manual tools will remain that way for the near future. But given the next-level abilities that digital tools can provide in terms of workflow management, efficiency, and compatibility for a wide range of users, it’s time for shops to take a second look at digital measurement.

If there were three main takeaways, I’d like you to walk away with, they’d be:

The features that extend digital gaging accessibility are built into the Windows operating systems and other software applications most everyone uses, just waiting to be unlocked and used to their fullest advantage.

Data reliability is more important than ever. The advanced functionalities afforded by digital gaging helps increase data accuracy and support measurement integrity, while eliminating the additional opportunities for error that come with manual processes.

Considering the current shortage of machinists, having technology available that opens the field up to more individuals to successfully fill these roles is an advantage for any organization.