Michal Grosenbach

Michal Grosenbach is the product manager, sensor & small tools, at Mitutoyo America Corp. (Aurora, IL). He can be reached at [email protected]. For more information, visit www.mitutoyo.com or call (888) 648-8869.

ARTICLES

Measurement

Data reliability is more important than ever.

Read More

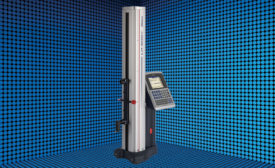

New Heights in Height Gages

Today’s multipurpose height gages can perform with near-CMM capabilities.

March 8, 2018

Measurement with Micrometers

With many different types of micrometers to choose from, how can you be sure to select the best one for the job?

October 1, 2016

Quality 101

Ins and Outs of Height Gages

Know your height gages for efficient and accurate measurements.

July 1, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing