In the field of quality assurance, the accuracy of measurement data is the foundation of effective decision-making. The equipment used to gather this data must be routinely and precisely calibrated to ensure its accuracy and reliability. Developing and documenting comprehensive calibration procedures has been a complex and time-consuming task. But artificial intelligence (AI) technologies can significantly streamline the process. This article explores how ChatGPT, an advanced AI language model, can be used to write detailed calibration procedures for various test and measurement equipment.

Understanding the Role of Calibration

Calibration is a comparison between measurements – one of a known magnitude or correctness made with one device, and another measurement made in as similar a way as possible with a second device. The second device, referred to as the unit under test (UUT), is the one undergoing calibration. This comparison provides a traceable link to ensure that measurements from the UUT are consistent with other measurements within the specified process’s parameters.

An Overview of ChatGPT

ChatGPT, developed by OpenAI, is an advanced version of the Generative Pre-trained Transformer series that uses machine learning to generate human-like text. ChatGPT employs a large neural network to analyze the relationships between words, sentences, and ideas in a dataset of text, and it uses this understanding to generate coherent and contextually relevant text.

Using ChatGPT to Write Calibration Procedures

ChatGPT is available for free on the OpenAI website or for mobile on both Google Play and the App Store. Presently, there are two models, GPT-3.5 and the newer, more advanced GPT-4, which is available only on paid plans. Generally, GPT-4 produces more detailed results, but either model should suffice for drafting calibration procedures.

A calibration procedure is a detailed, step-by-step process that a technician can follow to ensure a piece of measuring equipment is performing accurately. To use ChatGPT to write a calibration procedure, the user must provide it with detailed information about the equipment and the calibration standards used.

ChatGPT Meets Calibration

While AI cannot entirely replace human expertise in developing calibration procedures, it can certainly enhance and streamline the process. Doug Wheeler, the chief software architect at GageList Online Calibration Software, describes the meeting of ChatGPT and calibration.

While AI cannot entirely replace human expertise in developing calibration procedures, it can certainly enhance and streamline the process. Doug Wheeler, the chief software architect at GageList Online Calibration Software, describes the meeting of ChatGPT and calibration.

Listen to more Quality podcasts.

Here is a detailed guide on how to use ChatGPT for this purpose:

1. Define the Equipment and Calibration Standards: Start by drafting detailed information about the equipment to be calibrated and the calibration standards. Information needed includes the type of equipment, manufacturer details, model, the purpose of the equipment, the environment in which the equipment operates, and the measurement standards it should adhere to. This information will provide a basis for the AI to generate the initial draft of the procedure. Generally, it’s best to draft the inputs in a separate document, proofread and edit them, and then copy and paste them into the ChatGPT window.

2. Refine the Procedure: ChatGPT will generate a draft of the procedure, which will likely need refining. To guide the AI, ask specific questions or provide more information about each calibration step. For example, you might ask: What safety precautions should be considered during this process? or Provide more details on the setup for calibration.

3. Review and Validate the Procedure: Upon refining the procedure, it is essential to review it for accuracy and compliance with standards. This step may require professional expertise in the specific type of equipment or process. Any discrepancies should be noted and corrected before finalizing the procedure.

4. Iterate and Improve: Keep in mind that using AI to write procedures is an iterative process. The more feedback and information you provide to the model, the more accurate and detailed the procedures will become. Start broad and narrow the focus, then review the documents the AI produces for accuracy, consistency and style. Edit the procedure for proper formatting and style. Use your refined input formulas as templates for additional procedures.

Example: ChatGPT at Work

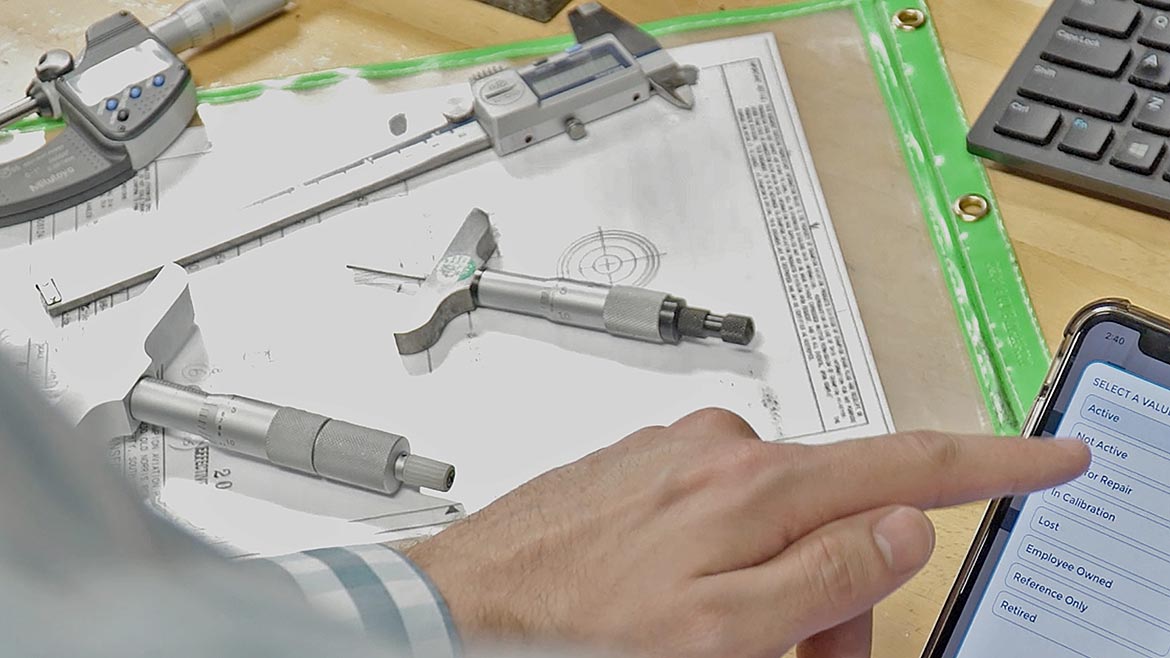

We wanted to find out how well ChatGPT would perform, so we fed it a prompt to write a detailed procedure for calibrating a Mitutoyo digital caliper. After some experimentation with additional details and instructions to ChatGPT we found the following prompts to provide an excellent first draft:

ChatGPT Prompt:

Act as my calibration technician and write a calibration procedure as follows:

Equipment Details:

- Type of Equipment: Digital Caliper

- Manufacturer Details: Mitutoyo

- Model: Mitutoyo 500-196-30

- Purpose of Equipment: The caliper is used for measuring inner and outer dimensions in various industrial applications.

- Operating Environment: This equipment is typically used in industrial environments that may include exposure to dust, moisture, and significant temperature variations.

Calibration Standards:

- Measurement Standards: The caliper should be calibrated according to the manufacturer's specifications. For dimensional measurements, it should be accurate to ±(0.001 inch).

- Regulatory Standard: The calibration procedure should adhere to the ISO 17025:2017 standard.

Structure the procedure to fit our standard document model as follows:

- Document Title

- Purpose

- Scope

- Responsibilities

- Equipment

- Procedure

- Documentation and Records

- Revision History (e.g., initial release)

ChatGPT Draft of Procedure:

This is the procedure that was produced:

Document Title: Calibration Procedure for Mitutoyo OD/ID Digital Caliper (Model: 500-196-30)

- Purpose: The purpose of this document is to define the standard procedure for calibrating a Mitutoyo OD/ID Digital Caliper, model 500-196-30, to ensure measurement accuracy within the manufacturer’s specified tolerances.

- Scope: This procedure applies to all instances of the above-mentioned calipers within the organization that require calibration.

-

Responsibilities

- The Quality Manager is responsible for ensuring the implementation and maintenance of this calibration procedure.

- The Calibration Technician is responsible for performing the calibration process following this procedure.

-

Equipment

- Mitutoyo 500-196-30 Digital Caliper to be calibrated

- Gage block set or certified length standards (traceable to national/international standards)

- Isopropyl alcohol

- Lint-free cloth

- Calibration sticker

- Calibration report form

-

Procedure

- Preparation

- Ensure the digital caliper is clean and free from dirt, grease, or any foreign material. Clean the caliper with isopropyl alcohol and a lint-free cloth, if necessary.

- Verify the gauge block set or certified length standards are within their valid calibration period.

- Calibration

- Turn on the digital caliper and ensure it is set to the desired unit of measurement (e.g., inches or millimeters).

- Close the jaws of the caliper and press the zero button to ensure it displays a zero reading.

- Measure the certified length standards or gauge blocks at the following intervals: 1 inch, 3 inches, and 6 inches (or equivalent in millimeters). For each measurement, ensure the caliper jaws are parallel and apply consistent pressure.

- Record the measurements in the calibration report form.

- Compare the recorded measurements with the certified values of the length standards. The difference between the measured values and the certified values should not exceed ±0.001 inch.

- If the digital caliper does not meet the tolerance limits, adjust the caliper according to the manufacturer's instructions and repeat the calibration process.

- Post-Calibration

- If the calibration results are satisfactory, complete the calibration report form and affix a calibration sticker to the digital caliper, indicating the calibration date, due date, and the technician's initials.

- If the calibration results are unsatisfactory, remove the caliper from service, and initiate corrective actions as per the organization’s non-conforming equipment procedure.

- Preparation

- Documentation and Records: All calibration results must be recorded on the Calibration Worksheet, including measurements, any observed errors, and calibration status. The date of calibration and the date of the next recommended calibration should be noted in the device’s record.

- Revision History: Version 1.0 – Initial release, 25th July 2023.

This procedure is intended to ensure that the Mitutoyo 505-736 Digital Caliper is calibrated according to ISO 17025:2017 standards. Changes to this document should be reviewed and approved by the appropriate personnel.

This procedure was produced in a nearly complete form, almost instantly, from the prompt we fed into the AI engine. We then edited and formatted it directly.

Advantages of Using ChatGPT for Calibration Procedures

There are several advantages to using AI to generate calibration procedures. Calibration is a body of technical information that can be communicated fairly easily by calibration professionals. But gathering, organizing and clearly documenting it in a standardized procedure format requires considerable effort, as well as a degree of writing talent. AI does most of the heavy lifting if the data that is provided is thorough and accurate.

Efficiency: AI can generate drafts of procedures much more quickly than a human writer, especially once it has been trained on specific types of procedures, saving significant time in the procedure writing process.

Consistency: AI models, unlike humans, do not have variations in their writing style or level of detail. They are able to produce more consistent procedures, which is critical in the field of calibration where precision and repeatability are essential.

Scalability: AI can generate any number of procedures without getting tired or needing a break, which makes it a scalable solution for organizations with large volumes of equipment to calibrate.

Conclusion

While AI cannot entirely replace human expertise in developing calibration procedures, it can certainly enhance and streamline the process. The ability of AI models like ChatGPT to generate human-like text, interpret complex instructions, and refine outputs based on feedback make them highly valuable tools in this field. By embracing AI technology, quality assurance professionals can improve the efficiency, consistency, and scalability of their calibration procedures.