In the realm of material science and engineering, the evaluation of material strength is crucial. One of the key methods for this purpose is compression testing, which measures the ability of a material to withstand compressive forces. In addition, the flexural modulus, often assessed alongside compression testing, provides further insight into a material’s resistance to bending. This article will shed light on compression testing and the significance of flexural modulus in assessing material strength.

Compression Testing

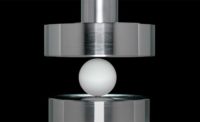

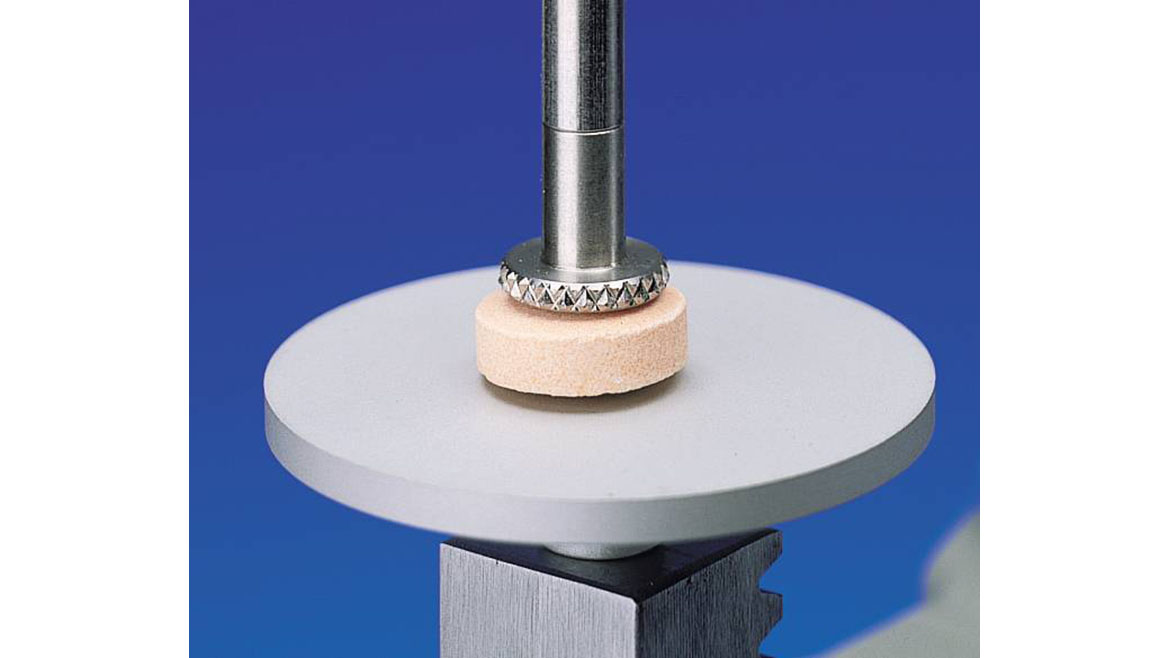

Compression testing involves subjecting a material to compressive forces until it deforms or fails. A sample is placed between an upper and lower fixture, such as parallel compression plates or specific application-driven fixtures. The fixtures are installed on a universal testing machine (UTM), and a gradually increasing force is applied until the material deforms to the desired height or force, or fractures.

UTMs utilize a strain gage-based load cell to measure force, and an internal encoder to measure distance. An extensometer, which clips on to the sample, more accurately measures small deflections, as the measurement is free from extraneous factors such as the UTM’s frame deflection and ballscrew inaccuracies.

UTMs are offered in single- or double-column configurations. For applications up to 5 kN, most systems utilize a single column, while the increased rigidity of a double-column is better suited to high-capacity machines. Very high-force systems, typically greater than 50 kN, may be hydraulically driven, while smaller systems are electromechanically driven with a ballscrew.

Depending on the complexity of the test method, compression measurements are expressed either in units of force and distance, associated with force measurement, or stress and strain, the foundational measurements of materials testing.

Force Measurement

Force measurement can determine material strength by measuring force and distance. Forces are expressed in units of lbF, N, or kgF, and distances as in or mm.

Some test methods require compressing the sample until failure, in which case the maximum force and distance at maximum force are required. For nondestructive test methods, distance at a specified force, or force at a specified distance are useful data points.

The profile of a plot of force vs. distance may provide additional detail about the behavior of the sample beyond a single result.

Materials Testing

Materials testing goes a step beyond force measurement by integrating sample geometry into the results. Instead of force, materials tests determine stress, which is equal to force divided by the cross-sectional area of the sample. Instead of distance, we measure strain, which is a calculation of percent deformation in the sample.

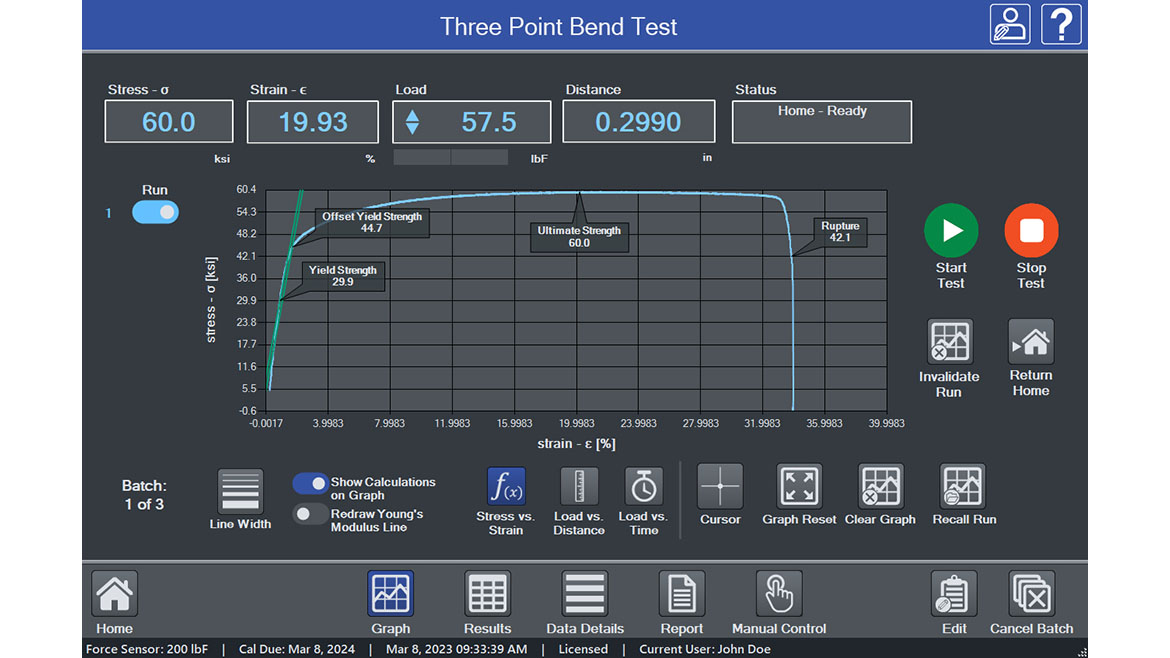

A plot of stress vs. strain is the basis for calculations such as elastic modulus, which is the slope of the elastic part of the curve, along with yield strength, rupture, and other values.

Flexural Modulus

In materials testing, the flexural modulus, also known as the bending modulus or modulus of elasticity in bending provides insight into the flexibility of a material of specific geometry.

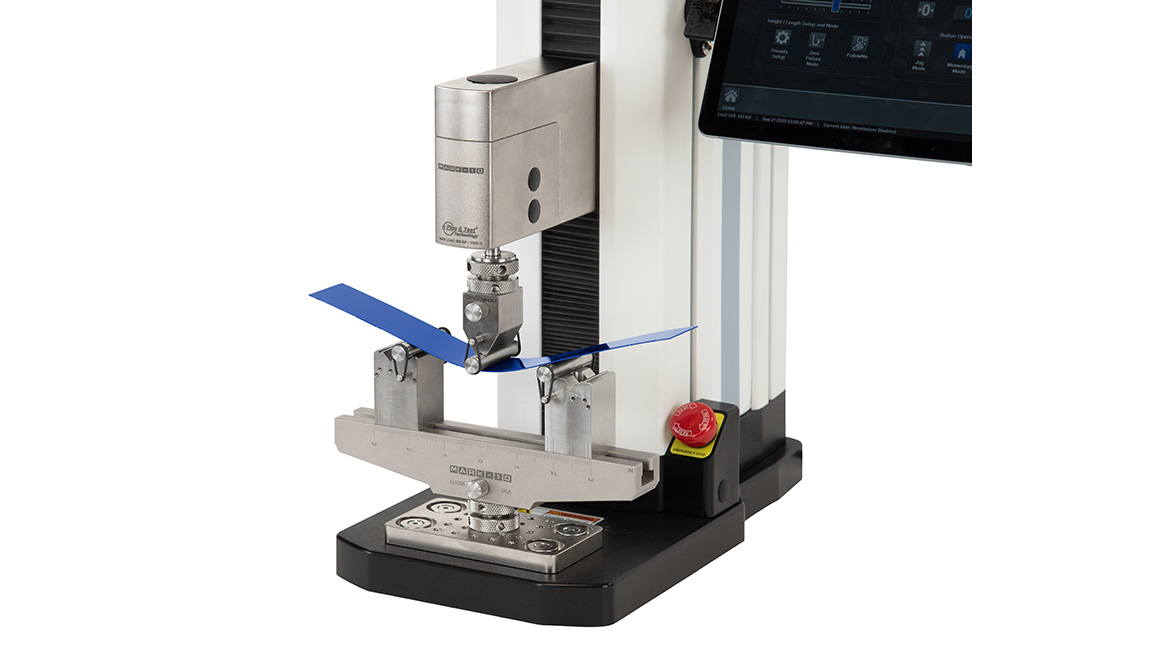

The flexural modulus is evaluated through a three-point or four-point bending test. A variety of bending fixtures have been developed where a sample is subjected to a bending load, causing a deflection. The relationship between the applied load and deflection determines the flexural modulus.

Bend fixtures can be fitted with one or two points, to accomplish a three- or four-point test. Blocks containing anvils can be positioned along the length of the fixture to widen or narrow the spacing as specified by the test method. Anvils of various diameters are also available, and may be interchangeable with certain block types.

Flexural modulus is calculated as follows:

Eflex = L3F ÷ 4wh3d

L = length between bottom fixture supports (span)

F = force (load)

w = sample width

h = height (sample thickness)

d = distance traveled (sample deflection)

Where to Start?

With this understanding of the basics of compression testing, let’s examine where such measurements are useful and how to get the ball rolling.

As with other quality control test objectives, compression testing is governed by thousands of testing standards around the world. Certain standards by ISO and ASTM are adapted globally, while others are developed for specific industries or geographic regions. When manufacturers determine that compression testing is necessary, but no standard test method can be identified, they may develop their own test method.

Whatever the procedure, it’s important to test samples consistently and repeatedly, so that trends and outliers can be properly identified from the results data.

Applications

Compression testing and assessing flexural modulus are essential for structural design and ensuring the integrity of load-bearing components. Materials with high compressive strength, such as concrete in construction, are desirable for their ability to withstand substantial compressive forces without failure. Similarly, the flexural modulus is critical for evaluating materials used in applications involving bending or flexing, such as beams, bridges, and other structural elements.

Compression testing can also be performed on a finished product, such as a spring. Compression springs are vital components in everything from writing pens to battle tanks. Measuring force and distance as a spring is compressed provides the needed data for spring manufacturers and OEMs, such as a mattress manufacturer, to ensure proper performance.

Lower-force applications include the materials used in golf clubs, skis, and other products, such as wood, plastics, and composites. On perhaps the most relatable level, the chips, crackers, cookies, and other foods we eat every day are enjoyable in part because they were evaluated under compression stress. The amount of “crunch”, “snap”, or “chewiness” is definable and quantifiable through food texture analysis, a subset of compression testing.

Quality Control and Material Selection

Compression testing and flexural modulus evaluation are pivotal in quality control and material selection processes. Manufacturers rely on these tests to ensure materials meet specified behavioral requirements and to identify potential weaknesses or defects.

NDT

A Quality Special Section

Manufacturers typically specify a tolerance range for critical results. Samples which fall within the range are suitable for sale, while those outside the range may require rework or disposal. To ensure specific behavior, certain test methods may also compare a test’s stress-strain curve to a “gold standard” reference curve.

By conducting these tests, engineers can make informed decisions about material suitability for specific uses, aiding in selecting optimal materials, ensuring intended performance characteristics, and preventing structural failures.

Research and Development

Compression testing and flexural modulus assessment are integral to research and development efforts. Scientists and engineers can explore new materials or modify existing ones to optimize stiffness properties. Novel manufacturing methods or materials recipes can also save costs and reduce environmental side effects, such as carbon emission or the ecological footprint of mining.

Conclusion

Advancements in materials science and engineering breakthroughs are possible through the science of compression testing. An investment in compression testing capabilities can quicken the pace of innovation and bring new products to market which are safer, more efficient, and sometimes even better for our planet.