PMI (positive material identification) has significantly evolved over time. Advancements in handheld XRF technology have led to improved accuracy, measurement speed, connectivity, and ease of use.

PMI was traditionally mostly carried out using portable optical emission spectrometers, which were often rather bulky and heavy, but around 30 years ago, handheld analyzers based on X-ray fluorescence (XRF) were developed, and became widely used for PMI applications a decade later, says Mathieu Bauer, senior application scientist and associate product manager for handheld XRF analyzers, Thermo Fisher Scientific.

Positive Material Identification Made Easy

Matt Kreiner, the head of Global Product Management at Hitachi High-Tech, discusses trends with PMI, how it can help manufacturers improve quality, and the benefits of on-site PMI.

Matt Kreiner, the head of Global Product Management at Hitachi High-Tech, discusses trends with PMI, how it can help manufacturers improve quality, and the benefits of on-site PMI.

Listen to more Quality podcasts.

"Technologies in the field have since expanded to also include laser-induced breakdown spectrometry (LIBS), which can measure carbon. Over this time, the power of X-rays and lasers has increased, improving the detection sensitivity of instruments and enabling shorter analysis times – generally just a few seconds. The size and weight of instruments have also decreased, improving ergonomics and ease of use," Bauer says.

The suite of tools available for PMI has expanded to meet growing needs, says Matt Kreiner, head of global product management, Hitachi High-Tech. For example, handheld X-ray fluorescence (XRF) instruments have become more capable to measure a wider range of elements; portable optical emission spectrometers (OES) have become smaller and lighter so they can reach more areas of the plant; handheld laser induced breakdown spectrometers (LIBS) have become faster and can also measure more elements than ever before, Kreiner says.

"In many cases, a combination of technologies is required to run a comprehensive PMI program, so manufacturers are looking for ways to simplify the user experience across their product lines, including in the digital space with regard to data handling," he says. "Most new instruments offer connectivity to cloud-based data services that can be used to collect, share and report results from PMI equipment. This connectivity will continue to develop as platforms grow and the solutions become more capable and flexible."

XRF technology has, over time, become more accurate and precise with the ability to identify a wider range of elements and materials, says Esa Nummi, vice president, X-ray mobile and portable analyzers, Bruker Nano GmbH.

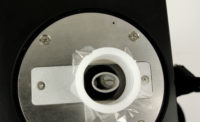

The latest silicon drift detector technology utilizes a graphene window protected by strong detector shield, which further enhances the instrument’s ability to identify alloys with low levels of light alloying elements such as Al or Si and improve its ruggedness," Nummi explains.

"Improved precision also enables the reliable measurement of critical trace and micro-alloying elements," Nummi says, and modern handheld XRF instruments can identify and analyze the elemental composition of most metal alloys in just a few seconds.

PMI technology has also evolved in terms of enhanced connectivity. PMI devices now offer enhanced connectivity features, enabling wireless data transfer and integration with other tools and software. These advancements allow for real-time collaboration and centralized management of PMI testing activities, Nummi says.

As with any industry, the needs of the PMI industry are constantly evolving, Kreiner says.

"Suppliers of PMI technology are paying attention and working closely with consumers, sometimes creating customized solutions for specific requirements," he says. "Testing demands are likely to continue to increase as companies strive to be more efficient and productive while becoming increasingly risk averse and intolerant of quality failures. PMI technology providers are eager to support these initiatives."

The emerging changes in how PMI data is analyzed, managed, and used could be even more impactful, Nummi says.

NDT Series

Positive Material Identification

"The integration of PMI devices with cloud-based data management systems allows for centralized data storage, analysis, and collaboration," Nummi says. "Industries can leverage cloud platforms to store large amounts of PMI data, perform advanced analytics, and generate actionable insights. This facilitates proactive decision-making, trend analysis, and the optimization of manufacturing processes."

In the future, AI and machine learning techniques will be applied to PMI data analysis to improve accuracy, automate material identification, and detect anomalies. By training algorithms with large datasets, AI can enhance the speed and precision of material identification, making PMI testing more efficient and reliable, Nummi says.

"Machine learning algorithms could also be used to identify patterns and trends in PMI data, enabling predictive maintenance and proactive quality control," Nummi explains. "All these emerging technologies and new opportunities for data management and analysis will make PMI an even more essential and impactful tool for manufacturing than it already is today."