Home » COVID-19

Articles Tagged with ''COVID-19''

Essential Testing for Essential Industries

Force measurement is an important characteristic in meeting the requirements of a quality product.

August 26, 2020

NDT News

NAM Survey: Manufacturers Continue Operating in Support of COVID-19 Response

August 5, 2020

From the Editor

Manufacturing Today

Manufacturers are adapting to a changing world.

August 3, 2020

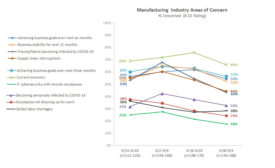

Manufacturers Respond to COVID-19

Our fourth COVID-19 survey explains what companies are doing now.

May 11, 2020

Guest Editorial Comment

Quality in the Time of COVID-19

What a world we’re living in.

May 1, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing