Test & Inspection

Test & Inspection

Anyone can buy a 3D printer and set up a shop, but there are a few essential things to know — especially when it comes to mesh repair.

Read More

Test & Inspection

Navigating the Nuances of Additive Manufacturing Quality Control

The evolution from traditional methods to additive manufacturing represents a paradigm shift.

February 16, 2024

Test & Inspection

Crushing it: a granular breakdown of testing what shouldn’t break down

While tensile testing garners significant attention, compression testing is equally crucial.

January 26, 2024

Test & Inspection

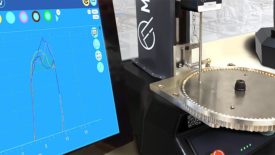

When Part Gaging is a Bottleneck

Automatic manual gauging improves process control, yield, and capacity.

January 26, 2024

Test & Inspection

Accelerated Weathering Testing: Guidelines for equipment and testing

January 18, 2024

Test & Inspection

Automated Testing Systems – Pushing the Envelope

How did we get here, where are we going, and is automation always optimal?

January 18, 2024

Automation

How Modern Warehouses are Redefining Efficiency Through Automation — Part 2

Insights into how AI, IoT, and blockchain are revolutionizing warehouses, enhancing transparency, and optimizing operational efficiencies.

January 17, 2024

Automation

Skilled Workers Pivot in an Automated Age — Part 1

Transitioning from repetitive tasks to specialized roles, with training as the key.

January 16, 2024

Test & Inspection

The Right Hardness Testing Method for Your Metals Application

The right hardness test method depends on the material being tested and the specific requirements of the application. Understanding the differences among the available options helps determine which method will give you the best results.

January 1, 2024

Test & Inspection

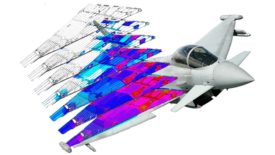

Phased array ultrasonic testing (PAUT)

Phased array ultrasonic inspection has become an indispensable tool in the aerospace industry, contributing to the safety and reliability of aircraft components.

December 31, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1705603301&width=275)