Articles by Edward McMenamin

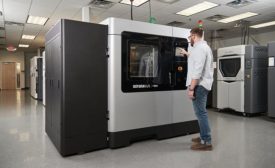

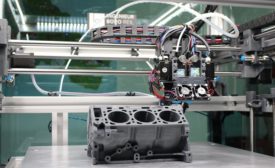

Data collection and quality elevate additive manufacturing to the factory floor.

Read More

Back to Basics: Testing Medical Equipment and Materials

Defects in medical devices and materials have life-or-death consequences.

December 3, 2018

The Role of Cameras in the World of Tomorrow

An industry expert discusses the present and future of machine vision cameras.

December 1, 2018

Back to Basics: Inspection Using High-Speed Video Cameras

High-speed video cameras capture what the human eye could never see.

November 2, 2018

Back to Basics: Detecting Heavy Metals Using X-Ray Fluorescence

Beginner tips to understand the role XRF plays in restricting hazardous materials.

October 2, 2018

Choosing the Right 3D Scanner

A quality engineer describes how he picks the right tool for the job.

October 1, 2018

Back to Basics: Impact Testing

Beginner tips to understand impact test methods and standards.

September 4, 2018

Where to Start with Ultrasonic Thickness Gaging

There are a wealth of resources for understanding the basics and newest advances in ultrasound.

August 15, 2018

Additive Manufacturing Standards Aim to Keep Pace with Technology

ASTM launches Additive Manufacturing Center of Excellence with industry partners.

August 1, 2018

Depth Gaging from Top to Bottom

A wide variety of depth gages are available for any application.

July 8, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing