Home » Keywords: » leak testing

Items Tagged with 'leak testing'

ARTICLES

Test & Inspection

Why zero drift occurs and ways to mitigate or even eliminate it.

Read More

NDT | Leak Test

Two-Point Calibration: The Key to an Accurate, Repeatable Leak Test

How single-point calibration falls short in pressure and vacuum decay leak test calibration.

January 10, 2024

NDT | Leak Testing

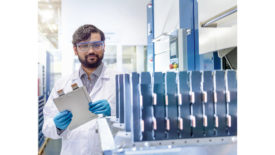

Leak Detection’s Crucial Role in Li-ion Traction Battery Production

Manufacturers that routinely challenge their leak tightness testing process will consistently produce products with reliable performance, battery longevity and safety.

January 9, 2024

Leak Testing

The Rise of Differential Pressure (DP) Decay Leak Testing in North America

What is DP and how are manufacturers using this test method to achieve better resolution and quicker cycle times?

July 6, 2023

NDT | Leak Testing

Race to Mobility Sharpens Focus on Leak Testing for Li-ion Batteries and Hydrogen Fuel Cells

There are thousands of places where a battery pack or fuel cell pack can leak.

June 13, 2023

Aerospace | Leak Testing

The How’s and Why’s of Leak Testing

In the aerospace field, old leak testing methods are replaced to improve efficiency and minimize time on the ground.

July 8, 2022

Aerospace | Back 2 Basics

Leak Test 101: The Basics Rule, No Matter How Much Technology Evolves

These best practices are relevant whether the right leak test for your application is pressure/vacuum decay, mass flow, or tracer gas.

July 15, 2021

NDT | Leak Testing

E-Mobility Gives Automakers a Host of Leak Detection Challenges

EV battery cells, battery packs, electric motors and other systems modified for EV applications all require leak testing to assure both quality and safety.

June 9, 2021

Standardized Leak Testing for Lithium-Ion Battery Cells

It is Essential for Automakers.

January 6, 2021

NDT Leak Testing

Supply, Demand and Cost: Don’t Let That Helium Just Drift Away at the End of a Leak Test

How can you make the most of this increasingly precious commodity for your critical quality assurance needs?

August 5, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing