Home » Keywords: » lenses

Items Tagged with 'lenses'

ARTICLES

Vision & Sensors | Machine Vision 101

Key Considerations When Selecting a Machine Vision Lens

There are 10+ considerations. Understand each and how they impact application performance.

April 25, 2024

Vision & Sensors | Case Study

Ultra Wide, No Distortion Lenses Tough Enough for Crash Testing

The results are speaking for themselves.

February 7, 2024

Vision & Sensors | Lenses

Understanding the Key Factors in Microscope Objective Performance

February 6, 2024

Vision & Sensors | Trends

What Drives the Trends in Machine Vision

Machine vision continues to grow somewhat faster than the GDP.

December 1, 2023

Vision & Sensors | Vision & Sensors 101

Part 2: The Impact of Miniaturization on Machine Vision Lenses

The push towards miniaturization is reshaping numerous industries, influencing design decisions and fostering innovation.

November 20, 2023

Vision & Sensors | Machine Vision 101

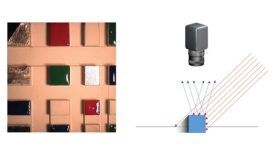

Optics 101: Assembling a Machine Vision System

Defining the needs of the system will refine the choices for types of cameras, imaging lenses, and illumination schemes.

May 1, 2022

Vision & Sensors | Machine Vision 101

Advancements In Telecentric Technology

As telecentric lenses become more compact, the overall footprint of vision systems will follow.

March 2, 2022

Vision & Sensors | Lenses

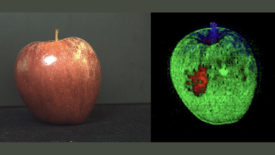

Optimizing Machine Vision Lenses For Different Wavelengths

The wavelengths used in any machine vision application have significant implications in choosing the ost appropriate lens.

March 1, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing