Home » Keywords: » leak detection

Items Tagged with 'leak detection'

ARTICLES

Electric Vehicles

Leak-Detection Standards for Electric Vehicles Long Overdue

Quality control lags behind rapid growth of EV sales in North America.

October 3, 2022

NDT | Leak Testing

E-Mobility Gives Automakers a Host of Leak Detection Challenges

EV battery cells, battery packs, electric motors and other systems modified for EV applications all require leak testing to assure both quality and safety.

June 9, 2021

Standardized Leak Testing for Lithium-Ion Battery Cells

It is Essential for Automakers.

January 6, 2021

NDT Leak Testing

Supply, Demand and Cost: Don’t Let That Helium Just Drift Away at the End of a Leak Test

How can you make the most of this increasingly precious commodity for your critical quality assurance needs?

August 5, 2020

NDT Leak Testing

Leak Testing Meets New Energy Storage Needs

Leak tightness is a major criterion for stable performance of a battery pack over the expected lifetime of an electrical vehicle.

August 5, 2020

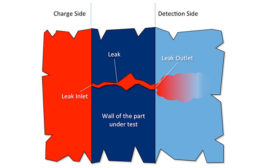

How Leak Testing Works

A leak test is a procedure used to determine if an object, product, or system functions within a specified leak limit.

February 8, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing