Home » Keywords: » CNC

Items Tagged with 'CNC'

ARTICLES

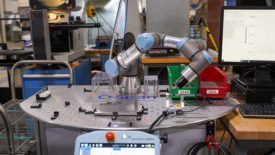

Quality in Automation | Automation

Leveraging automation for quality gains

As automation simplifies and enhances manufacturing processes, quality control staff see significant career advantages, making a shift towards more efficient, consistent, and data-driven production environments.

March 29, 2024

Quality 101

How Precision Measurement Tool Help Wave Worshippers Catch the Ultimate Barrel

Surf’s Up for Laser Trackers

November 1, 2023

Test & Inspection

Inspection Fixturing – Not A Question Of IF!

Whether you've been tasked with designing fixtures or sourcing them for your company, there are several details to consider.

February 8, 2023

Optimizing Machine Performance with Industry 4.0 and Calibration

Combining the latest in manufacturing technology with concepts that have been around for decades ensure quality products while minimizing unexpected shutdowns.

September 8, 2020

Automation: The Future of Manufacturing Is Here

Automation is especially useful in areas where manufacturers struggle to find enough skilled machinists to grow their business.

August 1, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing