Home » Keywords: » 3D Inspection

Items Tagged with '3D Inspection'

ARTICLES

CT provides unparalleled insight into a 3D structure, including its density at every point throughout its volume.

Read More

Time-of-Flight Forges Ahead

Time-of-flight technology presents a new set of opportunities for those developing 3D imaging systems.

March 3, 2020

Get Started with 3D Scanning

How to select a 3D scanning technology for your application.

September 1, 2019

Sponsored Content

Trends in 3D Inspection: Edge Computing, Acceleration, and 3D Smart Sensors for IIoT

October 30, 2018

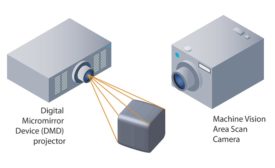

Photometric Stereo Technique

Photometric stereo technique offers a quick, efficient way to use 3D data for better machine vision.

September 4, 2018

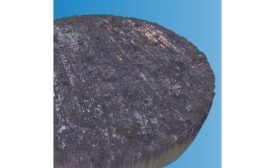

Fully Characterizing Brake Pad Materials to Improve Performance and Lower Development Costs

Combining benchtop mechanical testing of smaller brake material samples with rapid 3D surface metrology makes it possible to analyze results more quickly than ever before.

September 1, 2018

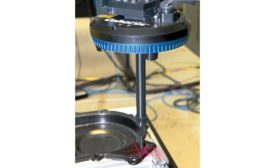

Inspection Technology Review for Automotive Bead Dispensing Process

The industry is trending toward 3D for inline bead inspection.

August 8, 2018

Modern UI Design for the Industrial Internet of Things

The move to smart, embedded devices running web technology is capable of fully realizing the potential of the IIoT.

December 1, 2017

Capturing the Third Dimension for Machine Vision

New technologies now in development may help make 3D more accessible for a larger number of manufacturers.

March 1, 2017

EVENTS

Webinar

11/8/23 to 11/8/24

Contact: Meg K.

Smart 3D Measurement Planning – It’s Easier Than You Think!

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing