Home » Keywords: » FDA regulations

Items Tagged with 'FDA regulations'

ARTICLES

Speaking of Quality | Mark Durivage

Consider preparing the workforce today for the challenges of tomorrow.

Read More

Software & Analysis

Quality Software: Core Qualities to Build Specialist Software Tools in QC Metrology

Manual operations cannot fully meet the challenges of a competitive and increasingly digitized industry.

March 28, 2023

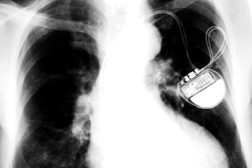

Manufacturing Medical

Medical devices warrant high levels of traceability in order to obtain, track and analyze data.

March 2, 2020

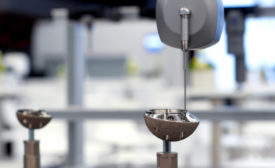

Metrology for the Medical Field

Medical devices require stringent quality and inspection methods.

March 1, 2020

Balancing Compliance and Continuous Improvement in Highly Regulated Industries

Learn how several innovative manufacturers are balancing compliance and continuous improvement in their operations.

October 8, 2019

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing