Home » Keywords: » thickness measurement

Items Tagged with 'thickness measurement'

ARTICLES

Measurement

Measuring and verifying the thickness of features is more critical than ever before.

Read More

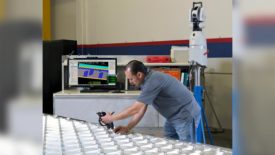

The Current State of Thickness Measurement

Optical measurement tools are picking jp steam, experts say.

June 29, 2020

Exploring the benefits of noncontact thickness metrology

Noncontact thickness metrology solutions have become a necessity for the manufacturing sector.

October 15, 2019

Sponsored Content

How to Reach Unrivaled Precision in Distance and Thickness Measurements with Confocal Sensors

April 8, 2019

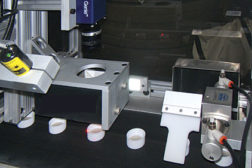

Thickness Measurement Basics

Whatever your material or its position, if it has a thickness, sophisticated tools exist to measure it.

December 1, 2015

Measurement

Measuring Thickness

It can be a bit more complicated than you’d expect.

March 3, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing