Home » Publications » Quality Magazine

Quality Magazine

2023 June

Cover Story

Back to TopFeatures

Back to TopDiameter Measurement

How to Measure Big IDs and ODs

As with any diameter measurement, there are several possible solutions.

June 7, 2023

Software & Analysis

Reverse Engineering Software For 3D

Once the model has been generated, you can use the software to analyze the model.

June 6, 2023

Medical

Best Practices for Validating CMM-based Inspection Processes

What does a thorough validation approach really entail?

June 1, 2023

Management | Robotics

As Robotics Gain Hold, Here’s How to Manage Them

The pandemic has only fueled the worker shortage, prompting manufacturers to embrace automation in large numbers. Senior leadership can ensure robotics are implemented correctly.

June 1, 2023

Quality 101

Building Blocks to Improve Organizational Culture

Lay out a road map to achieve organizational excellence and build a culture around it.

May 30, 2023

Columns

Back to TopFrom the Editor | Darryl Seland

Maps Have Been Helping Us for a Thousand Years

They've been helping us get where we are going for a thousand years.

June 15, 2023

Speaking of Quality | Mark Durivage

Competence, Awareness, and Training – Oh My!

Consider preparing the workforce today for the challenges of tomorrow.

June 5, 2023

NDT

Back to TopNDT | Computed Tomography

Industrial X-ray/Computed Tomography Operator Training: Turning Expectation into Actualization

The system’s potential remains locked inside the machine unless employees are properly trained to operate it.

June 14, 2023

NDT | Leak Testing

Race to Mobility Sharpens Focus on Leak Testing for Li-ion Batteries and Hydrogen Fuel Cells

There are thousands of places where a battery pack or fuel cell pack can leak.

June 13, 2023

NDT | Back 2 Basics

Industry Trends: Third-Party NDT Certification Programs Advance Digital Expertise, Standardize Industry Practices

The public deserves to have confidence in their NDT professionals.

June 12, 2023

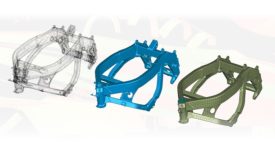

NDT | Additive Manufacturing

Technology Solutions for Large Applications in Additive Manufacturing

Understanding what technologies are available is the first step.

June 8, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing