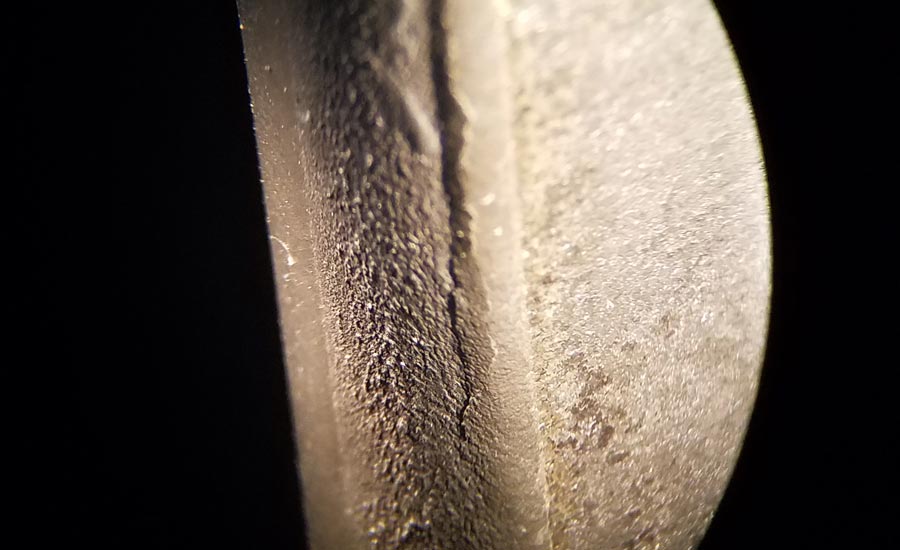

Nondestructive testing (NDT) is an extremely critical step in many industries. The safety of individual parts, entire systems, and even people can be directly tied to NDT. A single missed defect in an airline or spacecraft could cost millions of dollars and most importantly result in the loss of human life. For these reasons we need to ensure that NDT personnel are competent, qualified, and certified.

Each of these terms are separate things, but they can also interrelate. You can be competent but not be qualified or certified. You can be qualified and competent, but not be certified. If you are certified, you should be considered competent and qualified, but even that will only be in the specific method of your certification. Having a certification from an employer and not from a national or internationally recognized society or standard can, in some cases, still can mean you are not competent and qualified. This can typically only occur if the employer’s written practice does not conform to industry standards and guidelines or if there is outright fraud.

With all of this in mind, we need to look at what it takes to be competent, qualified and certified. We will only be focusing on Level I and Level II NDT personnel for this review. Level III personnel will be the focus of a future article.

The American Society for Nondestructive Testing (ASNT) states the following, “In order to determine competency, systems have been devised to ensure that NDT personnel have the proper training, have passed written and practical examinations, and have enough experience to properly perform NDT tasks using the applicable test method or technique. Personnel that have met all three of these requirements are said to be ‘qualified,’ and once qualified they can be certified, which is defined in several different ways under the various NDT systems.”1 This sounds reasonable right? The problem is that there are quite a few requirements listed in that statement. The main items are proper training, passing a written exam, passing a practical exam, and finally having enough experience to properly perform NDT tasks. We will look at each of these in more depth.

A single missed defect could cost millions of dollars and most importantly result in the loss of human life.

Proper training

This one seems clear. You need to have training in the science of the method and in the actual application of the method. The training requirements will be laid out in whatever standard or written practice you are working towards. These will have variations in the classroom contact hours and method performance, but they should be clearly defined.

Many training programs are available in the marketplace and most companies also have internal training programs available. The external programs are sometimes preferred by employers as the trainees will be fully engaged in the program and not be pulled away from any work-related issues. This external training will usually provide the trainee access to different tools and material than available at the employer. Internal training is also a good option, but this can involve the company trying to train multiple employees at once and using one of their higher skill NDT staff to conduct the training, so it can be quite costly and a large draw on resources.

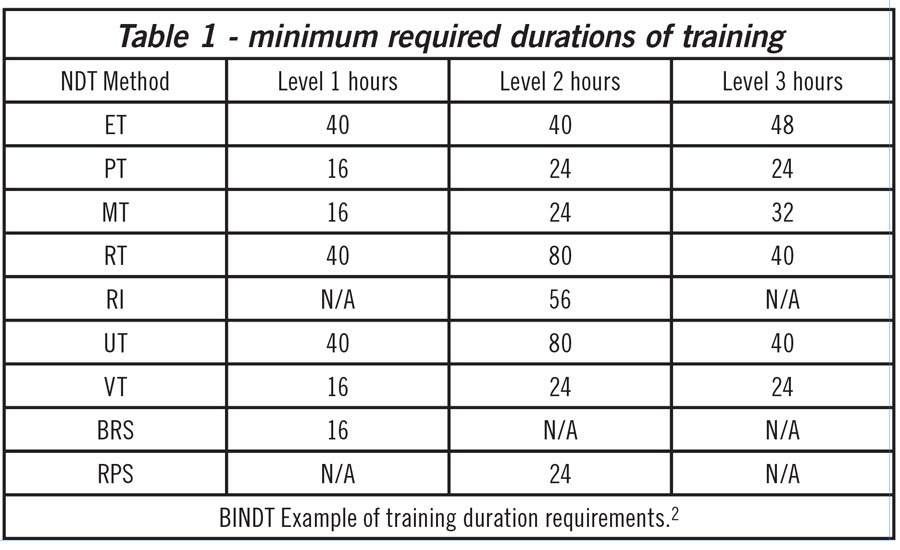

There is some variation of training hours/duration amongst the various NDT societies, but there will always be a minimum requirement that needs to be met. The table below is an example of the requirements from the British Institute of Non-Destructive Testing for PCN certifications.

Many training programs are available in the marketplace and most companies also have internal training programs available.

Experience

Here is where things get a bit tricky. ASNT’s SNT-TC-1a says that experience is “work activities accomplished in a specific NDT method under the direction of qualified supervision including the performance of the NDT method and related activities, but not including time spent in organized training programs.”3 There will be subtle differences in other certification requirements, but they are all quite similar, so we will use this one for discussion.

An important note is that your training hours cannot be included in your experience hours. Also, note that it states that the work activities need to be accomplished in a specific NDT method. For example, if you are working towards gaining experience in radiography (RT), but you spent six of your eight hours performing liquid penetrant (PT), what are you putting down in your training log for RT? It should only be the two hours you spent working in radiography. Your total time in any NDT method does matter and it does factor into the equation of experience required for certification, but if your eight-hour day only had two hours in RT, then that is what you should log for the day.

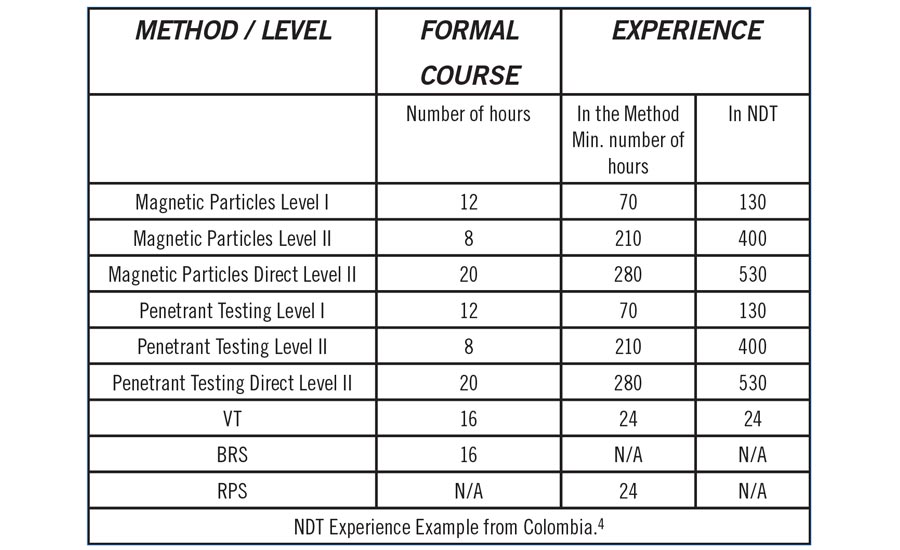

Here is an example of an industry requirement for experience. Notice that total time in NDT does count, but that a minimum hourly requirement in the method is key.

Another very important item in the SNT-TC-1a is the statement “performance of the NDT method and related activities.” This leaves some room for interpretation and, trust me, it gets a lot of interpretation. If you could do a random audit of most NDT experience log sheets you would find that most of them will have full eight-hour days logged. That would mean that everything you did in your eight-hour shift was performance of the NDT method and related activities. Seems a bit hard to imagine that in an eight-hour day everything you did fit into that definition.

I am not trying to infer that experience logs are purposely inflated, but when an audit is performed on your company, it would be wise to consider just how many direct experience hours an employee can fit into a given shift.

Pass a written exam

It is quite clear here again. There will be a written exam that covers a range of specific questions that is directly related to the method you are testing for. The exam should be comprised of two sections, the general and the specific. The general portion should come from a bank of random questions that covers the entire science of the method. The specific portion should address method specific equipment and the technique. These questions should be developed based on the equipment and techniques that are used in a company’s facility. Generally, there are 40 questions on the Level I and Level 2 exams and for Level III the number of questions ranges from 90 to 135 (depending on the method). Again, the questions should be randomly drawn from a larger bank of approved questions.

The exam questions need to be approved by a Level III. New questions should be written as new equipment, procedures, and techniques are developed and incorporated into the method. Incorporation of the newest material is very important as the new generation of the NDT workforce will be using these new developments more and more.

If you completed everything we just discussed, when did you become competent, qualified, and certified? The easy ones to determine are qualified and certified, but does this mean you are now considered competent?

The Cambridge Dictionary defines competent as “an important skill that is needed to do a job.”5 We can see through the discussion above that achievement of an NDT certification should meet this definition, but the emphasis I want to leave you with is that being competent requires continual engagement and refreshment of your skill. Level I’s are generally only certified for two or three years, so even if they are only performing the NDT occasionally, they should be keeping their skill or competence. Level II’s, on the other hand, can be certified for as many as five years. Five years is a long time. Anything over a couple of years is a pretty long time, so is it possible to lose your skill or competence in that time frame? I believe most of you would say yes. If you said yes to that, then you are agreeing that it is then possible to be both qualified and certified and NOT be competent.

Knowing just how important NDT is, please be sure to take away at least this one thing: Do everything you can to ensure that you keep your competence active, engaged, and evolving. Lives depend on it. NDT

- https://www.asnt.org/MajorSiteSections/NDT-Resource-Center/Codes_and_Standards/NDT_Certification_System.aspx

- https://docplayer.net/2031807-General-requirements-for-qualification-and-pcn-certification-of-ndt-personnel.html

- https://www.asnt.org/MajorSiteSections/NDT-Resource-Center/Codes_and_Standards/NDT_Certification_System.aspx

- http://isotec.com.co/en/our-services/8/capacitacion-de-personal-end

- https://dictionary.cambridge.org/us/dictionary/english/competency