Quality standards require that measuring equipment be calibrated prior to being put into service. In addition, the maintenance of measuring equipment requires recalibrations at regular intervals. There are many different types of calibrations, however, and simply saying something like “calibrate coordinate measuring machine (CMM)” when contracting the calibration of a CMM could lead to unforeseen quality risks. What method will be used? What tolerances will be checked, if any? Will accuracy adjustments be done? What kind of calibration certificate will be issued? Assumptions should not be made and, instead, organizations need to be clear in what they expect when hiring calibration services.

Many organizations today require ISO/IEC 17025 accredited calibrations, but simply requesting an accredited calibration is not enough. It is recommended that requests for calibration include much more clarity on what is needed. For example, for the calibration of a Mitutoyo CMM:

Calibrate Mitutoyo Crysta-Apex S 9106 CMM. ISO/IEC 17025 accredited calibration certificate required. Report as-found and as-left readings following method recommended by manufacturer or from a nationally recognized standard. Assess and report conformity to published manufacturer specifications using a simple acceptance decision rule with a test uncertainty ratio, TUR ≥ 4 . Include calibration due date on certificate using interval of 12 months. Perform cleaning, service, and accuracy adjustments as needed to bring unit into tolerance.

This language is designed to eliminate ambiguity and protect the customer. Anything that is not clearly stated is left for interpretation which leads to increased risks or wasted money. The following 10-point checklist is a good guide to contracting calibration services:

1. Use an accredited calibration service. There are many reasons to use a calibration service accredited to ISO/IEC 17025, the first of which is that accredited calibrations are required in many industries. Accredited organizations must submit to regular technical audits, which provides greater confidence in capability. All accredited organizations also have publicly available “scopes of accreditation” which provide for transparency of capabilities. Finally, accreditation requires demonstrating traceability which is critical in all measurements.

2. Define tests and methods. ISO/IEC 17025 recommends, but does not require, that calibrations are done following methods from published standards or as specified by the manufacturer of the equipment. Be very careful with any other methods, as their validity is questionable. Discounted calibrations may mean that less rigorous methods are being used, which increases risk to the customer.

Calibration of measuring instruments, such as a micrometer, is integral to maintaining quality standards. A gage block is still the most accurate method of checking linear range accuracy for small tools.

3. Define your tolerance limits. Most dimensional measuring equipment is calibrated to the manufacturer’s specified tolerance limits, but the end-user is free to define these. It is critical for the end-user to set their tolerance limits and not allow this to be determined by the contracting calibration service.

4. Check if capability is acceptable. All accredited calibration services have a scope of accreditation which lists what the organization is accredited to calibrate, over what range, and with what calibration measurement capability (CMC). The CMC represents the best measurement uncertainty the organization can report, and this can be used to quickly assess how good they are for a specific calibration. A common metric is to have the Test Uncertainty Ratio, or TUR, be greater than four, which means the calibration is at least four times more accurate than the tolerance being checked. A TUR lower than four is often acceptable, but never accept a TUR less than one, which would mean the calibration capability is worse than the tolerance being checked. By putting a TUR requirement in calibration requests, the customer is better protected and forces the supplier to disclose their capability in advance. The customer generally does not even have to know how to calculate TUR as any reputable calibration service can determine that for the customer.

5. Statement of conformity (pass/fail). One of the most important purposes of calibration is to determine conformity to specification; however, making such a statement is optional in accredited calibrations. The solution is to simply request the calibration service to assess and report conformity. The measured values, the tolerances, the uncertainty, and some sort of PASS/FAIL statement, with a defined decision rule, is needed.

6. Request as-found results. The as-found, or as-received, calibration results may be the most important part of calibration, as they are used to determine the stability of measuring equipment over time, which is used to adjust the calibration interval. For most calibration providers, the as-found results are optional. Be sure to request them.

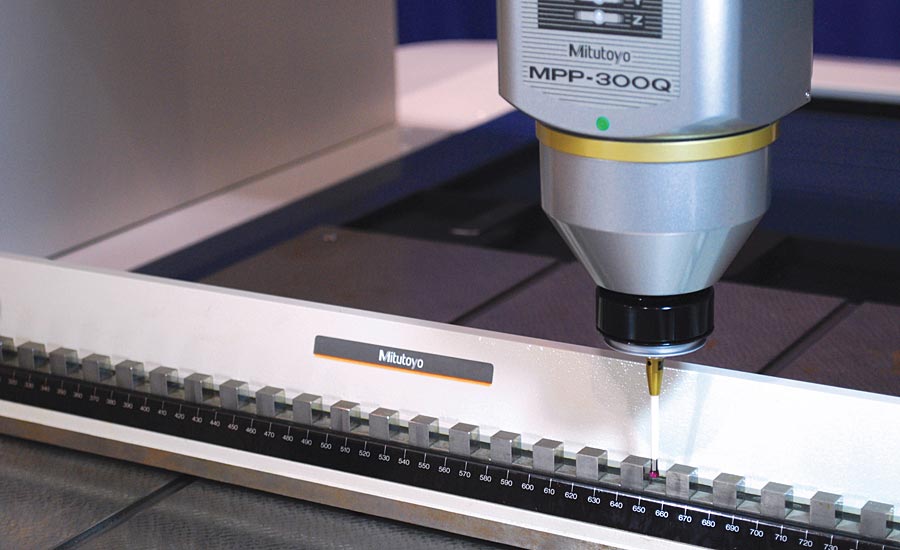

A step gage is used to calibrate the vertical and horizontal axis of a CMM. CMM calibration is important for keeping many machines in a lab or shop within the same tolerance standards for better quality control.

7. Adjustments and maintenance. For many customers, the concept of calibration includes correcting, setting, or adjusting the measuring equipment back to within tolerances. Unfortunately, the international definition of calibration does not include adjustments or maintenance. If the expectation from calibration is to adjust as needed, then this must be specifically requested. In addition, the ability of the calibration provider to make adjustments should be confirmed in advance, as the skills and tools to make adjustments are often different.

8. Define your calibration interval. Some customers do not realize that they are ultimately responsible for the calibration interval of their measuring equipment. While many customers use a one-year interval, the intervals should be lengthened or shortened based on the historical performance of the measuring equipment and taking risk into consideration. For example, in precision manufacturing in harsh environments, a digital caliper may need a three-month interval; however, that same caliper used for low accuracy wood working may not need to get recalibrated for 25 years. For accredited calibrations, the calibration due date can only be provided on the certificate with customer agreement.

9. Request accredited certificate. There is a subtle yet important difference between using an accredited calibration provider and receiving an accredited calibration certificate. Some calibration providers charge extra for an accredited calibration certificate. Be careful here – a non-accredited certificate from an accredited organization is the same as using a calibration provider that is not accredited. To avoid this confusion, be certain to request an accredited calibration certificate.

10. Rules for calibration label. The purpose of calibration labels is to allow the user of the measuring equipment to readily identify calibration status. However, there is limited guidance or rules on what needs to be done in calibration for a new calibration label to be applied. While organizations may have their own internal rules, if those rules are not communicated to the calibration provider, then a new calibration label may be applied with different expectations. This can be a big problem. For example, calibration labels are routinely applied in cases where the measuring equipment has not been compared to specifications. If the idea of non-conforming equipment still receiving a new calibration label is concerning, then be certain to define the expectations when contracting the calibration service.

Calibration is critical in the proper implementation and maintenance of measuring equipment. When done correctly, calibration helps ensure quality and reduces risk. It is important to clearly define expectations when contracting calibration services. Some contract language and a 10-point checklist have been outlined to enable customers of calibration services to maximize their calibration dollars and minimize their risk.