Measurement

Measurement

How IoT Integration Enhances Quality and Speed, Part 2

IoT’s real-time analytics and in-process control are making operations more precise and products more reliable.

May 2, 2024

Measurement

Precision Trends in Metrology, Part 1

The integration of 3D CAD models and advanced software algorithms are setting new standards for accuracy and efficiency in manufacturing.

May 2, 2024

Face of Quality | Jim L. Smith

Measuring the Right Things Lead to Organizational Excellence

May 1, 2024

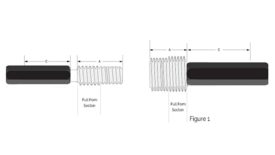

Gaging

Setting Thread Rings for Accurate Quality Checks: A Step-by-Step Guide

Following these steps meticulously will guarantee the ongoing reliability and effectiveness of your thread ring gages.

April 16, 2024

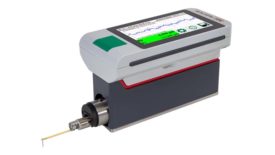

Measurement

Ensuring Precision: A Guide to Calibration in Surface Finish Measurement

The calibration process for surface finish units is simple but essential to the manufacturing process.

April 12, 2024

Measurement

The Definition of a Fool is a Drowning Man Who Tries to Keep It a Secret

A Story on Purchasing the Wrong Equipment and Keeping It.

April 8, 2024

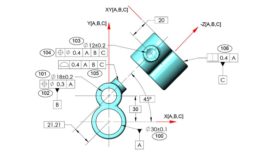

Measurement

Better Measurement Data Reporting to Improve GD&T Effectiveness

ASME Y14.45-2021 Standardizes Measurement Data Content for GD&T Specifications.

April 4, 2024

CMS Column | Justin Novak

How Has Metrology Changed in the Past 40 Years?

A lot has happened since 1984, and we're just getting started.

April 3, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing