Home » Keywords: » reverse engineering

Items Tagged with 'reverse engineering'

ARTICLES

Sponsored Content

3D Scan-to-Print Technology Restores Creative Outlet for Paraplegic Artist

3D Printing a Prototype

January 5, 2022

Software & Analysis

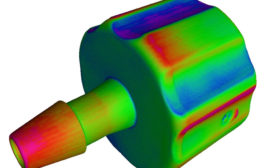

Practical Reverse Engineering

Choosing the right tools for the job.

December 6, 2021

How CT Scanning Is Enhancing the Quality and Manufacturability of Medical Devices

This inspection technique is highly valuable for industrial metrology.

November 8, 2018

Reviving Legacy Parts through Reverse Engineering & 3D Scanning

Reverse engineering and quality control will continue to be growing applications for 3D scanning technology, along with newer opportunities in virtual and augmented reality.

November 1, 2018

Reverse Engineering: Outputs

Learn more about these eight options using 3D scanning.

March 6, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing