Home » Keywords: » styli

Items Tagged with 'styli'

ARTICLES

Quality 101

Don't sacrifice quality by using the wrong styli and probe extensions.

Read More

Test & Inspection

The Most Common Styli Used Today

Let's discuss the most common styli used today.

November 30, 2022

Achieving the Ideal Measuring Room with the Right Accessories

It’s critical to optimize your measurement machines and quality program with the right tools for your application.

September 1, 2019

The Ideal Stylus System

Choosing the right components and construction impacts your measuring result

September 1, 2018

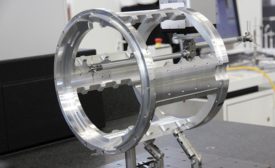

Specialty Styli for CMM Operators and Machinists

The solution is often a special stylus.

December 1, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing