Home » Keywords: » x-ray

Items Tagged with 'x-ray'

ARTICLES

New Product

Evident Scientific Next-Generation Vanta Handheld XRF Analyzers

January 23, 2024

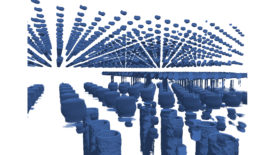

NDT | Computed Tomography

The most effective and precise battery inspection technology

It’s the tiniest defects that are the major problems today.

January 8, 2024

NDT | Computed Tomography

Creating the Future of Mobility with CT Inspection of Batteries

Industrial x-ray and CT inspection supports quality control and failure analysis at all stages of a battery's lifecycle.

September 21, 2023

NDT | Radiography

Why Additional Training Is Needed When Transitioning From Film Radiography To Digital Radiography

It is essential to have additional formal training to understand key image quality requirements.

February 14, 2023

NDT | XRF

How to Measure Metal Coating Thickness Using Handheld X-ray Fluorescence Analyzers

Handheld XRF is an indispensable tool in quality assurance that provides multiple benefits.

February 8, 2022

NDT | Trends

Monitoring Assets with Restricted Access Phased Array

Corrosion is complex, and mitigating and managing it is not a linear process.

August 15, 2021

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing