Home » Keywords: » 3D vision

Items Tagged with '3D vision'

ARTICLES

The importance of reliability in EV batteries is paramount to the overall vehicle performance.

Read More

Vision & Sensors | System Integration

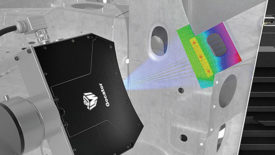

The Power Of Embedded GPU-Driven Smart Sensor Acceleration

There are four common reasons manufacturers would need to use a smart vision accelerator to enhance the inspection performance of their sensor.

July 6, 2022

The Hybrid Approach

Combining the best of traditional machine vision and deep learning.

January 12, 2021

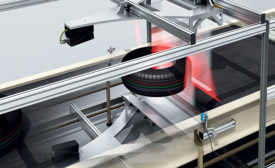

Machine Vision Trends for Today’s Industrial Age

Improvements in machine vision include advanced-imaging analysis, robotics, machine learning and 3D vision.

November 26, 2020

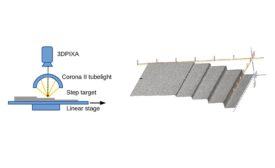

3D Stereo Camera Repeatability Measurement

Understand the process to determine measurement repeatability of a stereo 3D camera.

September 1, 2019

Simple Steps to VGR Implementation

Vision technology is constantly being updated, especially where speed and resolution are concerned.

January 1, 2019

The Resurgence of Vision Guided Robotics

Manufacturers that have dismissed the use of robotics in the past are now taking a fresh look due to advancements in machine vision technology.

July 1, 2018

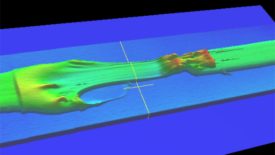

The High-Speed Trend

Automating Manufacturing Processes with High-speed 3D vision improves quality and drives down costs.

March 1, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know with Quality’s comprehensive coverage of the manufacturing and metrology industries.

SIGN UP TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing